Invention (Patent Application Publication): Sporring

SL, Olsen O, Lauritzen JB, Andersen TL, Brondsted P, Bechgaard K, Hansen JG,

Jensen H, Almdal K, Mouritsen S. Medical device for insertion into a joint, WO2006133711A2 (2006).

WO2006133711A2 Denmark

Worldwide applications 2006 WO EP 2008 US

Application PCT/DK2006/000343 events:

2006-06-14 Application filed by Cartificial A/S

2006-06-14 Priority to EP06753312A

2006-12-21 Publication of WO2006133711A2

2007-06-14 Priority to PCT/DK2007/000290

2007-09-20 Publication of WO2006133711A3

2008-12-09 Priority to US12/331,335

Medical device for insertion into

a joint

Sune Lund

Sporring, Ole Olsen, Jes Bruun Lauritzen, Tom Løgstrup Anderson, Povl Brøndsted,

Klaus Bechgaard, Jan Guldberg Hansen, Henrik Jensen, Kristoffer Almdal, Søren Mouritsen

Abstract

The present invention relates to implants used for

alleviating and/or preventing conditions relating to damaged joints involving

articulating surfaces. The implants com- prise fibre of polymer and/or metal,

and can be used as an artificial joint, as part of an artificial joint or as an

artificial joint spacer made to replace the missing cartilage or to improve the

slidability between two natural and/or artificial components of the body, or

between a natural and artificial component. The product of the invention can be

used to partly or entirely coat medical products or to make up implants partly

or entirely.

Description

Medical

device for insertion into a joint

Field of invention

The present invention relates to a method and a medical

device for alleviating and/or preventing conditions relating to damaged joints

involving articulating surfaces. Especially the present invention relates to

medical products which are coated partly or entirely by one or more polymeric

components and to medical products which comprises metal and polymeric

materials. The product of the present invention can be used as an artificial

joint, as part of an artificial joint or as an artificial joint spacer made to

replace the missing cartilage or to improve the slidability between two natural

and/or artificial components of the body, or between a natural and artificial

component of the body. All patent and non-patent references cited in the

application, are also hereby incorporated by reference in their entirety.

Background of invention

At present, joint damage, such as cartilage damage, is

treated by replacing the joint with an artificial joint. However, serious

complications are caused by the replacement of artificial joints, in particular

a high occurrence rate of loosening problems resulting in breakage of the bones

around the artificial joint. In the case of cartilage damage a repair with

cartilage substitution placed into intact bones is to be preferred instead of

replacing the entire joint.

In particular, the invasive character of the fixation of the

prostheses such as anchoring of the prosthesis with screws and pins results in

numerous side-effects such as risk of infection, loosening as mentioned above,

damage on excising bone due to interruption of blood supply and necrosis.

A device for replacement within a joint should preferably

enable the normal function and movements of the joint. Weight-bearing joints,

in which movement in more than one direction takes place, are normally rather

difficult to replace. A prosthetic device should enable the normal movement of

the joint. During walking, the normal movement of for example the hip joint

corresponds to about 37°-41 ° flexion/extension, 2°-14° adduction/abduction and

a rotation of about 2°-16°. During movement from standing to sitting position a

flexion of hip joint corresponds to a movement from 0 to 90 degrees. When

studying the movement of femoral caput to the acetabulum the latter movement

includes a rotation of 90 degrees.

Many medical devices are implanted into load-bearing joints

such as knees, hips, etc, or utilised in the human body where mechanical

function provide high strength or shape stability such as heart valves, breast

prosthesis, stent, catheter, etc. As such, these medical devices must be very

strong and possess a high degree of wear resistance. Prosthetic medical devices

manufacturers constantly work toward developing better products by improving

their physical properties. Improved wear resistance, for example, is a

desirable quality to impart to a prosthetic medical device. Improving wear

resistance without losing strength or causing oxidative degradation is a

difficult balance to obtain.

A need for improved prosthetic medical devices with improved

wear resistance exists.

Many implants produce small particles on the surface of the

implant when subjected to motion. The particles are liberated from the implant

as abrasion caused by the motion of the implant and friction towards other

components within the body. These particles can give rise to inflammation

within the individual where the implant is implanted. In a test controlling the

wear characteristic of a hip-joint implant with traditionally polyethylene (PE)

acetabular cups, about 1012 particles are produced pr. million of

movements (cycles).

The use of ceramic or cross-linked PE cups slightly reduces

the number of particles produced. Still the produced particles give rise to

inflammation and also there is a risk that the implant becomes loose.

An implants produced with a smooth UHMWPE coating according

to the present invention will only produce 5*108 or less particles pr.

million cycles. Thus a lesser degree of inflammation and a longer life of these

implants are some of the results when implanted into an individual.

Summary of invention

The present invention relates to medical devices which may

be used in damaged joints involving articulating surfaces.

The medical device may comprise at least one fabric of one

or more polymer fibre and/or of one or more metal fibre and/or a 3D network of

polymer fibre and/or metal fibre. The at least one fabric may also be at least

one 2D network. Fabrics, 2D networks and 3D networks may be used together in

one medical device.

The volume within the fibres making up the device may be

filled up with one or more polymer optionally further comprising one or more

metal components or the volume is filled with a metal or metal alloy. The

volume to be filled up with one or more polymer optionally further comprising

one or more metal components can be determined according to the shape and total

volume of the final device ready to use. The device may be subjected to

size-reducing processes during preparation, thus the initially volume defined

by the fibres of the fabrics and/or networks can be larger than the

corresponding volume within the final device.

Biocompatible polymers and biocompatible metals can be used

to make up the device. Polymers and metals are described elsewhere herein.

A device or part of a device made up according to the

present invention may be used for any implant. Especially implants to be

positioned into joints can be made, such as an acetabular cup, a spacer to be

located between an acetabular cup and a head of hip stem, or an interpositional

arthroplasty. The head of the hip stem can be made of metal or a ceramic

material. The device may also be a cup shaped spacer which is positioned

between the natural femoral stem or a metal femoral stem and a natural

acetabular cup or a prosthetic acetabular cup.

The medical may comprise at least a first surface area,

wherein at least a first poly- meric component optionally further comprising

one or more metal components is attached to or coated on the first surface

area. The material to coat a medical implant can be made with fabrics, 2D

networks and/or 3D networks of polymer fibre and/or metal fibre where the fibre

are connected to each other or with another polymer and/or metal material as

described herein.

A medical device produced from the materials described

herein as well as devices produced by other methods may be coated or covered

partly or entirely with a polymeric material of the present invention, the

polymeric material optionally comprises a metal component.

The medical device may have an upper surface, a lower

surface and at least one edge and wherein at least the one edge may be sealed

by a collar. The collar can be made of a material according to the present

invention, e.g. it can be made with fabrics, 2D networks and/or 3D networks of

polymer fibre and/or metal fibre where the fibre are connected to each other or

with another polymer and/or metal material as described herein.

Also the collar may be made of a first, second and/or a

third polymeric component optionally further comprising one or more metal

components.

A surface of the device can be made smooth by using the

material according to the present invention. The device comprises at least a

first and a second side, wherein the at least first side is made of a first

polymeric component optionally further comprising one or more metal components

and wherein the part of or the entire of the first and/or second side has a

frictional resistance of less than 0.5 Newton.

The smooth surface can be made by using a material according

to the present invention, e.g. it can be made with fabrics, 2D networks and/or

3D networks of polymer fibre and/or metal fibre where the fibre are connected

to each other or with an- other polymer and/or metal material as described herein.

The smooth surface may further include one or more cavities.

The device may have at least one through-going perforation

which is not for liga- ments. The perforation may have a diameter of at least

0.01 mm and can conduct liquid from one first side of the device to another

second side of the device. The liquid may be synovial fluid or a physiological

salt solution and/or another biocompatible liquid.

The device may also be equipped with an inner volume between

the first and second side and where said liquid can be within this volume. This

inner volume may further comprise a network of at least one polymeric and/or

metal component, e.g. polymeric fibres and/or metal fibres.

The surface of a medical device according to the present

invention may be a self- healing surface. The medical device comprises a first

polymeric component optionally further comprising one or more metal components

which may be self-healing when subjected to injury before implantation, during

implantation and/or after implantation.

The self-healing surface can be made by using a material

according to the present invention, e.g. it can be made with fabrics, 2D

networks and/or 3D networks of polymer fibre and/or metal fibre where the fibre

are connected to each other or with another polymer and/or metal material as

described herein. Other polymers described herein can also be used to produce a

self-healing surface.

The surface material may be any material described herein,

e.g. a composite polymeric component optionally further comprising one or more

metal components. The device can include a microencapsulated healing agent that

is released upon injuries hereby polymerization of the polymeric component is

triggered by contact with an embedded catalyst/initiator. The healing agent can

be monomers of the first polymeric component and/or of a second polymeric

component.

The medical device according to the present invention may be

two parts or units which fit into each other, the device comprise at least a

first unit with at least a convex surface and a second unit with at least a

concave surface, where the convex and concave surface is congruent with each

other and the first unit fit partially or entirely into the second unit, and

the first and/or second unit comprises at least one polymeric component

optionally further comprising one or more metal components. Each unit can be

made by using a material according to the present invention, e.g. it can be

made with fabrics, 2D networks and/or 3D networks of polymer fibre and/or metal

fibre where the fibre are connected to each other or with another polymer

and/or metal material as described herein.

The first

and second unit can have substantially similar sizes, or be of different sizes.

The units may be movable when compared to each other, and the units can

continue to be in contact during a movement of the body and/or return to be in

contact when a movement is finished.

The medical device according to the present invention may

comprise at least an upper layer, a first middle layer and a lower layer, wherein

the upper layer and said lower layer is made from one uninterrupted piece of at

least a first polymeric component optionally further comprising one or more

metal components.

The material to make up the device may be a fabric, 2D

network and/or 3D network which can be constructed in one piece, which is

folded around an axis and hereby forming the upper and lower layer.

The upper and lower layer of the device may be similar or

substantially similar in size, and may be formed from a tube folded around the

axis. The tube may have a uniform diameter along the length, or may contract in

a first and/or a second end of said tube, e.g. the tube contract in the axis.

The device may in the axis further com- pris at least one aperture.

The medical device according to the present invention may

also be thicker at the periphery of the device. The device may comprise at

least a first polymeric component optionally further comprising one or more

metal components, wherein the device has a middle area which at least in one

dimension is surrounded by an outer area, and wherein the thickness of the

outer area at least partly is larger than the thickness of the middle area, and

the outer area ends in at least one edge of said device. The device may have

any suitable shapes, e.g. cup-shaped or approximately cup- shaped, and wherein

a middle area is the top and an outer area is a skirt. The skirt may be thicker

that the top.

The device may also be a layered device. The device in a

layered structure may comprise

• at least one upper layer of said first polymeric component

optionally further comprising one or more metal components,

• a middle layer of said second polymeric component

optionally further comprising one or more metal components, and

• at least one lower layer of said third polymeric component

optionally further comprising one or more metal components, where the chain

length of the first polymeric component and the third polymeric component is

longer than the chain length of the second polymeric component.

In a layered device as described above, each layer may

itself be composed of at least two sub-layers of polymeric fabric and/or a 2D

network and/or a 3D network, each sub-layer optionally further comprising one

or more metal components constructed of the polymeric components described

herein, and at least one layer of polymeric film optionally further comprising

one or more metal components, said polymeric film constitutes a layer between

the two layers of the polymeric fabrics and/or 2D network and/or 3D network.

Also the middle layer, the film may further comprise one or

more metal components.

The metal used in the device may be one or more metals

selected from the group of metal and metal alloys of titanium, gold, silver,

chromium-cobaltum, zirconia, cobalt- chromium-molobdenum alloy and Stainless

Steel alloys and/or a ceramic of one or more of these metals and alloys. Other

metals may also be included e.g. in the alloys.

The polymers and metals including alloys used may be in the

form of e.g. a powder, granulate, chopped fibres, long fibres, 2D structural

components like plates, 3D structural components like shaped plates or

hemicircles with holes. Also a combination of these forms may be used. Instead

of using fabrics, 2D networks and/or 3D networks of polymer fibre and/or metal

fibre to produce the devices as described above, it may also be possible to use

polymers and/or metals which are suitable for injection moulding, these

materials may further include components of polymer and/or metal, as described

herein.

Description of drawings

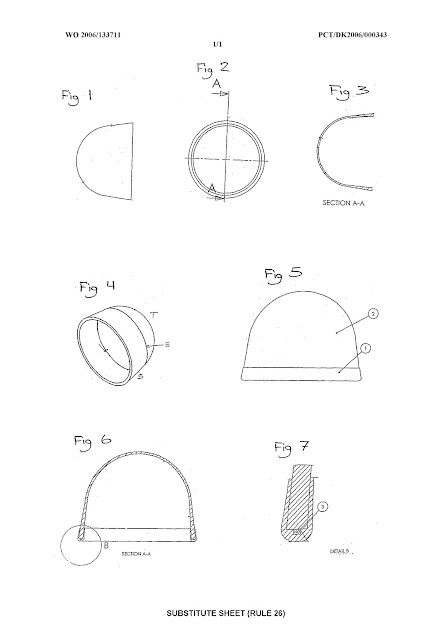

Fig. 1 illustrates a longitudinal section of a cup-shaped

medical device.

Fig. 2 illustrates a cross-section of a cup-shaped medical

device.

Fig. 3 illustrates a longitudinal section of a cup-shaped

medical device. The device has a shirt in which the material is thicker than

the material at the top of the device.

Fig. 4 illustrates a cup-shaped medical device. The line

denoted "E" illustrates equator, which is the border between the top

"T" and the shirt "S".

Fig. 5

illustrates a cup-shaped medical device (2) with a collar (1).

Fig. 6 illustrates a longitudinal section of a cup-shaped

medical device. The device has a shirt in which the material is thicker than

the material at the top of the device. Furthermore the device has a collar with

a marker.

Fig. 7 illustrates the edge of the medical device in Fig. 6.

The edge is enclosed by a collar, and this collar supports a marker (3).

Detailed description of the invention

The present invention provides a desirable balance of

improved wear resistance and high tensile strength and toughness in the

polymeric compositions used for medical devices. The implants may also include

metal e.g. as a composite with polymeric materials. It has been discovered that

wear resistance can be improved without sacrificing other desirable properties

such as toughness or strength by controlling the amount of different polymeric

and/or metal substrate comprising the prosthetic device. The products of the

invention has a high tensile strength and improved wear resistance as well as

the capability to absorb shocks, impacts and pressure load, also it reduces the

amount of tearing off.

The medical device may be designed to occupy the pelvis cup;

to occupy at least part of the intra-articular cavity to partly or completely

fill the role of natural cartilage within a joint; and/or to be an interpositional

arthroplasty. The devices or their units may be designed so as to occupy the

whole of the cavity or merely a portion of the intra-articular cavity, such as

the portion of the cavity where cartilage is worn or where much of the pressure

is exerted.

The medical devices may also be designed to replace at least

part of a bone within a joint together with the intra-articular cavity to

partly or completely fill the role of the bone which is replaced and to partly

or completely fill the role of natural cartilage within a joint.

The material for the medical devices is primary polymers

although other materials as described elsewhere herein can be used. The other

materials e.g. metals may be used together with the polymers.

In an aspect of the invention a medical device comprises at

least one fabric of one or more polymer fibre and/or of one or more metal fibre

and/or a 3D network of polymer fibre and/or metal fibre. The polymer fibre and

metal fibre which may be used are described elsewhere herein.

In an embodiment the device comprises an area at least

defined by the outermost fibres of the network, this area is filled up with one

or more polymer optionally further comprising one or more metal components or

said area is filled with a metal or metal alloy. The polymer and metal

components used may be anyone described elsewhere herein. The fibres of the

network may during the production process of the device be located

substantially in the position where the fibres will be located in the final

device. Also the fibres making up the network may during the production process

be located in different positions when compared to the location of these fibres

in the final device. Hereby the volume to be filled up may be defined by the

outermost fibres of the network and is a volume defined by the corresponding

volume of the network in the final device, hereby the volume defined by the

network of fibres is larger in the production process than the volume defined

by the final device.

In the production process heat and/or pressure may be used

to connect polymers and/or metals in different forms to each other.

In an embodiment the polymer fibre and/or the polymer

optionally further comprising one or more metal components may be a polyolefin,

such as polyethylene, such as UHMWPE. Also other polymers as described

elsewhere herein may be used. The polymer fibre and the polymer optionally

further comprising one or more metal com- ponents can be different types of

polymers. Also the metal fibre and the metal components can be different types

of metal.

In an aspect of the invention a medical device comprises at

least a first surface area, wherein at least a first polymeric component is

attached to the first surface area.

In an embodiment of the device, the first surface area is a

part or the entire surface area of a first volume, where the first volume is

smaller than the final volume and where the final volume is the total volume of

the device before implantation, and wherein the difference between the final

volume and the first volume is a volume made up by at least a first polymeric

component, a first metal component or a combination of a first polymeric

component and a first metal component.

At least a first polymeric component and/or a first

polymeric component together with a first metal component can coat a part or

the entire surface of an implant. A second and/or third polymeric component or

a combination of a second and/or third polymeric component together with a

second and/or third metal component may coat the same surface part as coated by

the first polymeric component, optionally together with a first metal

component, or the second and/or third polymeric compo- nent, optionally

together with a second and/or third metal component, may coat a part of the

surface or different parts of the surface than coated by the first polymeric

component optionally with a first metal component.

The term "first volume" is used to describe the

produced implant or part of an im- plant at a stage in the production where

only a coating according to this invention is lacking on the implant. This

definition does not exclude the possibility of treating the coated implant e.g.

by irradiation or by a liquid solution and thus the final volume being the

coated implant slightly can change in volume.

In an embodiment the first volume has a shape which

corresponds to the final volume of the device before implantation. In this case

"corresponds to" can mean having exactly the same shape just with a

smaller volume, or can mean that the overall shape is similar when comparing

the first volume and the final volume, but in one or more zones the two volumes

correspond to a lesser degree to each other than in other zones.

In a further embodiment the first volume corresponds to at

least 50% of the final volume, such as at least 60%, such as at least 70%, such

as at least 80%, such as at least 85%, such as at least 90%, such as at least

95%, such as at least 97%, such as at least 99%. This calculation can be made

based on the overall shape of the first and final volume or can be based on a

comparison between different although related zones of the first and final

volume of the implant.

In an embodiment the first volume corresponds to a lesser

degree to the final vol- ume in areas where the at least first polymeric

component optionally together with a first metal component, is attached. If

only a part of the surface of the implant is to be coated with the first

polymeric component and/or second polymeric component and/or third polymeric

component, optionally together with a first, second and/or third metal

component, respectively, the zones including the surface area to be coated will

correspond to a lesser degree to the final volume of the implant than zones

located elsewhere in the implant.

In an embodiment the first volume further comprises

different first zones, and where the different first zones are smaller volumes

of the first volume and the first volume in different first zones corresponds

to a different degree to related final zones of the final volume, and where the

final zones are smaller volumes of the final volume. The zones of the first

volume and final volume are not of a specific volume, but are to be determined

from implant to implant. When a zone of a first volume corresponds to a zone of

a final volume, this means the two zones are located in similar areas of the

implant when taking into account that the final volume is larger than the first

volume.

In an embodiment the volume of the first zones corresponds

to at least 50% of the volume of the related final zones, such as at least 60%,

such as at least 70%, such as at least 80%, such as at least 85%, such as at

least 90%, such as at least 95%, such as at least 97%, such as at least 99%.

In another embodiment the volume of the first zones

corresponds to a different degree to the volume of the related final zones and

where the different degree is selected between 50-100%, such as 60-100%, such

as 70-100%, such as 80-100%, such as 90-100%, such as 95-100%, such as 50-90%,

such as 60-90%, such as 70- 90%, such as 80-90%, such as 50-80%, such as

60-80%, such as 70-80%, such as 50-70%, such as 60-70%. Some zones of the first

volume may be relatively smaller than other zones when compared to the related

zones of the final volume.

In another embodiment the first volume further correspond to

the final shape of the final volume. Only slight differences exist between the

shape of the first volume and the shape of the final volume.

In an embodiment the first surface area comprises the outer

surface of one or more of the first zones. The number of zones constituting the

first surface area can be calculated if a zone is defined as a volume of the

implant where the zone(s) next to this zone have or is going to have a coating

that differs in thickness or overall polymeric composition when compared to the

zone of interest.

In an embodiment the at least first polymeric component is

attached to the entire outer surface of the first volume. An implant can be

coated over the entire outer surface with the first polymeric component,

optionally together with a first metal component and/or a second polymeric

component, optionally together with a second metal component and/or a third

polymeric component, optionally together with a third metal component. In an

embodiment the device at least in the first area is subjected to wear when the

device is located in an individual. An implant can be coated either in only the

area(s) which are subjected to wear or also in other areas. The polymeric

components, op- tionally together with metal components, used as coating are

described elsewhere herein and can be one or more polymeric components

optionally together with one or more metal components.

In an embodiment the first volume of the device may be made

partly or entirely of polymer, bone and/or metal. The implant to be coated can

be made of any material which can be coated by one or more polymeric

components, optionally together with metal components, as described elsewhere

herein.

In implants composed of different units, one or more of

these units can be coated partly or entirely by the polymeric components

described herein, the polymeric components may comprises metal components as

also described elsewhere herein.

In an embodiment the first polymeric component, optionally

together with one or more metal components, constitute at least 1% of the

entire outer surface of the device, such as at least 3%, such as at least 5%,

such as at least 8%, such as at least 10%, such as at least 15%, such as at

least 20%, such as at least 25%, such as at least 30%, such as at least 35%,

such as at least 40%, such as at least 50%, such as at least 60%, such as at

least 70%, such as at least 80%, such as at least 90%, such as at least 99%.

This calculation is based on a comparison of the outer area of the first volume

and the outer area of the final volume.

In another embodiment the first polymeric component

constitute at least 1% of the diameter of the final volume of the device, such

as at least 3%, such as at least 5%, such as at least 8%, such as at least 10%,

such as at least 15%, such as at least 20%, such as at least 25%, such as at

least 30%, such as at least 35%, such as at least 40%, such as at least 50%,

such as at least 60%. This calculation is based on a comparison of the diameter

of the first volume and the diameter of the final volume, and can be an overall

calculation or a calculation within one or more zones. In an embodiment the

first polymeric component, optionally together with metal components, may be

located at the outside of the device in areas that is subjected to wear when

located in a body. The implant can be coated only in areas that is subjected to

wear, or in other areas too. It is important to coat the implant in the areas

subjected to wear.

In an

embodiment the first polymeric component, optionally together with metal

components, is in the form of a fabric. The first, second and third

component, optionally together with metal components, can be in any form described

herein and can be combined in any way as described elsewhere herein.

In an embodiment the first and the second polymeric

component comprises the same monomeric component or the same components of the

composite material, and the first and second polymeric components are

differently crystallized within the implant ready to implant. The first and the

second polymeric component may comprise a first and/or second metal component.

These metal components may be similar or different types of metal or the same

type of metal although in pieces of different sizes e.g. short fibre and long

fibre.

Also the third polymeric component can be of the same

monomeric component or the same components of the composite material as the

first and/or second polymeric component, and/or be differently crystallized

within the implant ready to implant when compared to the first and/or second

polymeric components. The third polymeric component may comprise a third metal

component. This metal component may be of similar or different types of metal

than the first and/or second metal component, or the same type of metal

although in pieces of different sizes e.g. shorter fibre and/or longer fibre

In an embodiment the first and the second polymeric

component comprises the same monomeric component or the same components of the

composite material and the first and second polymeric components have different

morphology within the implant ready to implant.

Also the third polymeric component can be of the same

monomeric component or the same components of the composite material as the

first and/or second polymeric component and have a differently morphology

within the implant ready to implant when compared to the first and/or second

polymeric components.

In an embodiment the first polymeric component and/or the

second polymeric com- ponent and/or the third polymeric component, each

optionally comprising one or more metal components may be attached to the first

volume by ultrasound welding, laser welding, heating and/or gluing. Any method

to secure the polymeric components to the first volume can be used.

In an embodiment the first polymeric component and/or the

second polymeric component and/or the third polymeric component, each

optionally comprising one or more metal components are attached to each other

before attached to the first volume. The polymeric components, optionally

comprising one or more metal components, can be attached to each other e.g. in

a layered structure as described else- where herein, but also other

compositions described herein can be used.

In an embodiment the first polymeric component and/or the

second polymeric component and/or the third polymeric component, each

optionally comprising one or more metal components, are attached to the first

volume one polymeric component at a time. The polymeric components, optionally

comprising one or more metal components, can be attached to the first volume of

the implant in any order suitable for the implant, thus the first polymeric

component need not be the polymeric component situated closest to the first

volume. The number and order of the polymeric components, optionally comprising

one or more metal components, are not limited.

In an embodiment the number of layers of the polymeric

components, optionally comprising one or more metal components, includes more

than one layer of one of the polymeric components, optionally comprising one or

more metal components, and each of the layers are attached to the first volume

one polymeric component at a time. Preferred number of layers is described

elsewhere herein.

In an embodiment the said device comprises a part of or an

entire hip joint prosthesis with a natural or metal and/or ceramic femoral stem

articulating against an acetabular cup to be placed in the pelvis. The

acetabular cup may be a PE acetabu- lar cup, a UHMWPE acetabular cup or a metal

acetabular cup, and the metal or ce- ramie femoral stem and/or the acetabular

cup may be covered according to the possibilities described elsewhere herein.

In an aspect of the invention a device comprises an

acetabular cup or socket to be inserted in the pelvis cup, where the acetabular

cup may be made of any polymeric material and which may be covered and/or

reinforced with long polymeric fibre. The fibre may be in any form as described

elsewhere herein.

The long polymeric fibre which may cover and/or reinforce an

acetabular cup, may be in the form of one or more fabric or one and/or more

layers of fibre as described elsewhere herein or may be a 3D-structure. The

device comprising fabric and/or layers of fibre may be produced as described

elsewhere herein. In this context a 3D- structure is a composite made of a 3D

(three-dimensional) network of polymer fibre and/or metal fibre filled with and

optionally entirely surrounded by a polymeric com- ponent. The 3D-network may

have a knitted, crochet and/or weaved structure or may be made by any other

method described elsewhere herein. The polymeric component to fill out the 3D

network may be any polymer mentioned elsewhere herein.

Preferred is an acetabular cup as described above where the

long polymeric fibre are UHMWPE fibre, and the polymeric material to fill out

the space between the fibre has a melting point below the melting point of the

used UHMWPE fibre.

More preferred is an acetabular cup as described above which

may be covered with a fabric (2D-network) and/or a 3D-network of UHMWPE fibre,

and where the polymeric material to fill out the space between the fibre is a

polyethylene (PE) material. The PE material to fill out the space between the

fibre may be only one type of PE or may be PE of different length.

In an embodiment the acetabular cup as described above may

be used together with a cup-shaped spacer made in accordance with the

description elsewhere herein.

In an aspect of the invention the device is part of a hip

joint prosthesis or another prosthesis, and the device comprises a spacer

between two parts of a prosthesis or between a part of a prosthesis and a

natural bone of an individual. In a preferred embodiment a cup-shaped spacer is

positioned between the natural femoral stem or a metal femoral stem of a hip

joint prosthesis and a natural acetabular cup or a prosthetic acetabular cup.

In another embodiment the device is a spacer to be

positioned between two natural bone parts of an individual e.g. as an

interpositional arthroplasty.

In an aspect of the invention, the device includes at least

a first polymeric compo- nent optionally with a first metal component, and the

device has a middle area which at least in one dimension is surrounded by an

outer area, and wherein the thickness of the outer area at least partly is

larger than the thickness of the middle area, and the outer area ends in at

least one edge of the device.

In an embodiment the middle area of the device is surrounded

by the outer area in two dimensions. The device may have any shape suitable to

be allocated into a joint of a mammal. The device may be flat or substantially

flat. Furthermore the device may cup-shaped. Other shapes are described

elsewhere herein.

In another embodiment the device is homogenous in dimensions

around an axis, and the axis is a central axis according to one dimension of

the middle area. The axis indicates a line separating the device into two

substantially equally sized units.

In an embodiment, the device is heterogeneous in dimensions

around an axis, and the axis is an approximately central axis according to one

dimension of the middle area. The axis indicates a line separating the middle

area of the device into two substantially equally sized units. The outer area

is larger on one side of the device than on other sides of the device.

In an embodiment the middle area and the at least one edge

are in different planes. The device is non-homogeneous in shape and

non-homogenous with respect to the planes of the edges.

In an embodiment at least one edge are in different planes.

One edge is in one plane and at least another edge is in another edge, and when

these planes are pro- jected to a similar plane, this similar plane constitutes

an outline of the edge or edges of the device, and the outline has a shape that

is selected from a shape from triangular to circular.

The shape of the device may be any possible figure in each

dimension where the shape may constitute a surface being flat, curved, waved,

undulated, bent, bowed, crooked, while the overall shape of the device may be

but is not limited to circular, oval, triangle, squared, rectangle, cubed,

bowl, cup, crown, cap, basin, heart, egg, kidney, figure of eight, preferred

shape is cup or hemispherical. The thickness of the device may also vary, as

described elsewhere herein.

In an embodiment the device is cup-shaped or approximately

cup-shaped, and the middle area is a top and the outer area is a skirt.

In the cup-shaped device with a rounded top, a line separating

the top and the skirt is equator, and the outmost part of the skirt is the edge

of the device. Equator is located around the cup-shaped device where the

curvature of the cup changes to follow the tangent to the cup.

The cup-shaped or approximately cup-shaped device may have a

substantially uniform thickness all over the device or the device may have

various thicknesses. Preferred is a top of a first thickness and a skirt wit a

second thickness. The second thickness can be at least 25% larger that the

first thickness, such as at least 50%, such as at least 75%, such as at least

100%, such as at least 125%, such as at least 150%, such as at least 175%, such

as at least 200%, such as at least 225%, such as at least 250%, such as at

least 300%, such as at least 350%, such as at least 400%, such as at least

500%.

Preferred is a cup-shaped device with a second thickness

that is about 200% of the first thickness.

In an embodiment the thickness of the outer area is at least

5% larger than the thickness of middle area. The thickness of the middle area

is measured at the location where the middle area is thinnest and the thickness

of the outer area is measured at the location where the outer area is thickest.

The thicker outer area compared to the middle area provide the device with an

increased stability in the outer area, especially when compared to a device

with a uniform or substantially thickness as of the middle area. The stability

of the device implies that the device to a lesser degree bent or flex in the

outer area when located in the joint. Especially a cup-shaped or substantially

cup-shaped device has the advantages as mentioned.

In the manufacture of the device a polymeric material

optionally comprising one or more metal components as described elsewhere, has

to be spread within the device. This becomes easier when the outer area is

thicker than the middle area. Thus a reproducible production of uniform devices

or substantially uniform devices becomes more steady, hereby increasing the

quality of the devices.

A further advantage of a thicker outer area than the middle

area of the device is that it is easier to finish or close the edge of the

device. The device can be closed by a collar as described elsewhere herein.

A thin device increases the flexibility of the device,

hereby the mammal such as a human is subjected to lesser degree of

inconveniences when the device is located in a joint of this mammal. A thick

outer area thus increases the stability of the device without decreasing the

stability of the device.

In an embodiment the device further comprises at least a

second polymeric compo- nent optionally comprising a second metal component,

wherein the chain length of the first polymeric component may be longer than

the chain length of the second polymeric component.

A device according to the invention comprises at least a

first polymeric component and a second polymeric component, each optionally

comprising one or more metal components, wherein the chain length of the first

polymeric component is longer than the chain length of the second polymeric

component. The first polymeric component is providing the physical properties,

such as strength of the device as discussed below. Due to the longer chain

length the strength, in particular the tensile strength, of the device is

increased. The chain length of the first polymeric compo- nent is preferably

above 100 monomer units, such as above 120 monomer units, preferably above 150

monomer units. The chain length of the second polymer is preferably at most 99%

of the chain length of the first polymer, such as at most 95%, such as at most

90%, such as at most 80%, such as at most 70%, such as at most 60%, such as at

most 50%, such as at most 40%, such as at most 30%, such as at most 20%, such

as at most 10%, such as at most 5%.

In an embodiment the first polymeric component is selected

from polymers having a carbon-backbone.

The first polymeric component may be selected from

polyacrylates, polystyrene, polyethers, polytetrafluorethylene,

polyvinylalcohol, polyethylene, polypropylene, polyolefinic polymers,

polyethylene, polypropylene, polyethylene oxides, polyvi- nylpyrrolidon,

polysilanes, polyurethanes, polyethers, polyamides, polyesters, polyalkyl

acrylates, nylon, rubber and epoxy resins. It should be understood that the

above list of polymers is not exhaustive, and other polymers may also be

employed in the present invention. Preferred is polyethylene and polypropylene.

Most preferred is polyethylene.

When the device is constituted by two polymeric components,

each optionally comprising one or more metal components, the second polymeric

component may be selected from polyacrylates, polystyrene, polyethers,

polytetrafluorethylene, polyvinylalcohol, polyethylene, polypropylene, polyolefinic

polymers, polyethylene, polypropylene, polyethylene oxides,

polyvinylpyrrolidon, polysilanes, polyurethanes, polyethers, polyamides,

polyesters, polyalkyl acrylates, nylon, rubber and epoxy resins. Preferred

combinations for the first and the second polymeric component are polyethylene

and polypropylene, polyethylene and polyethylene, or polypropylene and

polypropylene, in the latter two cases, the first and the second polymeric

components is comprised of identical monomers, whereas the polymers thereof are

of different chain length. When the monomers of the two polymeric components

are identical the prosthetic device is preferably compounded to form a

bidispergent system.

The device is to be substantially composed of polymeric

material optionally compris- ing one or more metal components, particularly

solid or semi-solid polymers. Poly- mers are the family of synthetic or natural

macromolecules consisting of inorganic, organic polymers and combinations

thereof. Organic polymers may be natural, synthetic, copolymers, or

semisynthetic polymers. Natural polymers comprise of the class of compounds

known as polysaccharides, polypeptides, and hydrocarbons such as rubber and

polyisoprene. Synthetic polymers comprise elastomers such as nylon, polyvinyl

resin, polyvinyl chloride, polyvinyl dichloride, polyvinylpyrrolidone,

polyethylene, polystyrene, polypropylene, polyurethane, fluorocarbon resins,

acry- late resins, polyacrylates, polymethylmethacrylate, linear and

cross-linked polyethylene, phenolics, polyesters, polyethers, polypyrolidone,

polysulfone, polyterpene resin, polytetrafluoroethylene, polythiadiazole,

polyvinylalcohol, polyvinylacetal, polyvinyl oxides, and alkyds. Semisynthetic

polymers may be selected from cellu- losics such as rayon, methylcellulose,

cellulose acetate and modified starches. Polymers may be atactic,

stereospecific, stereoregular or stereoblock, linear, cross- linked, block,

graft, ladder, high, and/or syndiotactic. The term graft polymer is in- tended

to mean copolymer molecules comprising a main backbone to which side chains are

attached. The main chain may be a homopolymer or copolymer and the side chains

may contain different inorganic or organic constituents.

The device may comprises cross-linked polymers elastomers

such as high consis- tency elastomers, rubber, elastin and collagen. The

material may be selected from polyurethane, elastin, collagen and combination

products thereof. Alternative embodiments of materials suitable for the surface

of a device according to the invention include, in addition to the materials

mentioned supra and infra include hyaluronic acids and derivatives thereof.

Preferred polymeric materials are however presently believed

to be those selected from the group comprising polyolefins, such as polyethylene,

polypropylene, polybu- tene, polyisoprene, and polyvinylpyrrolidone,

combinations thereof, their copolymers, and grafted polymers thereof,

particularly polyethylene and polypropylene, most particularly polypropylene.

These polymers may be combined with metal, which is in a form described

elsewhere herein.

Preferably, the polymer materials of the first, second

and/or third polymer layer, each optionally comprising one or more metal

components, may be from the group of polyethylenes or the group of polypropylenes

such as polyethylene (PE), polypropylene (PP), high molecular weight

polypropylene (HMWPP), high molecular weight polyethylene (HMWPE), ultra high

molecular weight polyethylene (UHMWPE) and ultra high molecular weight

polypropylene (UHMWPP), high density polyethylene (HDPE), low density

polyethylene (LDPE), high density polypropylene (HDPP) and low density

polypropylene (LDPP), ultra high density polyethylene (UHDPE), ultra high

density polypropylene (UHDPP), cross-linked polyethylene, non-cross-linked

polyethylene, cross-linked polypropylene, and non-cross-linked polypropylene.

In this embodiment of the present invention, any combination of polymers listed

above, or their equivalents, may be used. These polymers may be combined with

metal, which is in a form described elsewhere herein.

In an embodiment the first, second and/or third polymeric

component is a composite material. The device may be fully or partly fabricated

of a composite material. This composite material may be a fibre-reinforced

composite material comprising fibre embedded in a polymeric matrix. After

embedding of a fibrous material in a polymeric matrix, the resultant

fibre-reinforced composite material is shaped and is partially or fully cured

to the point of sufficient hardness to provide a component for use in the

fabrication of the medical device.

The reinforcing fibre element of the fibre-reinforced

composite may be formed of one or more materials selected from the group

consisting of: graphite fibre, polyaramid, polyesters, polyamides, nylon fibre,

carbon fibre, glass fibre, collagen fibre, ceramic fibre, polyethylene fibre,

poly(ethylene terephthalate), polyglycolides, polylactides, stainless steel

fibre, cobalt-chrome alloy, titanium, titanium alloy, or nickel-titanium shape

memory alloys, biocompatible polymeric materials, and other natural and

synthetic materials compatible with the polymeric matrix.

The composite materials can also include reinforced

plastics, or polymers which are laminated or layered or reinforced with one or

more other materials such as nylon, graphite fibre, Kevlar.RTM. fibre,

stainless steel fibre, etc., nylon fibre, carbon fibre, glass fibre, collagen

fibre, ceramic fibre, polyethylene fibre, poly(ethylene terephthalate),

polyglycolides, polylactides, and combinations thereof.

The polymeric matrix element of the fiber-reinforced and

particulate-filled compos- ites is selected from those known in the art of

materials used for medical devices, including but not being limited to

polyamides, polyesters, polyolefins, polyimides, polyarylates, polyurethanes,

vinyl esters or epoxy-based materials. Other polymeric matrices include

styrenes, styrene acrylonitriles, ABS polymers, polysulfones, poly- acetals,

polycarbonates, polyphenylene sulfides, and the like. Other polymeric mate-

rials mentioned herein can also be used.

The reinforcing material may be in the form of a network of

fibre formed of one or more materials as mentioned above, where the network is

embedded in one or more polymers. The network or the fibres are embedded in a

polymer, where the poly- mers are described elsewhere herein.

In the method of the present invention, the device is made

after the embedding of the fibre with a polymeric matrix. After embedding of

the fibre, the resultant composite material is formed into, for example, a long

bar and cured or polymerized to a hardness whereby the bar may be cut and/or

machined without deforming the structural integrity of the bar. The bar is

preferably cut into short segments and is ready for use in the fabrication of

medical devices. The bars may be used as they are or may be further modified by

cutting, grinding, machining, heating and shaped and the like to provide a

specifically shaped or customized component.

The medical device in accordance with the present invention

is preferably formed from a fiber-reinforced composite material comprising a

polymeric matrix and reinforcing fibre within the matrix. The fibre are

embedded in the matrix manually or mechanically by a variety of techniques

including, but not limited to matched die proc- esses, autoclave moulding,

resin injection moulding (RIM), sheet, dough and bulk moulding, press moulding,

injection moulding, reaction injection moulding, resin transfer moulding (RTM),

compression moulding, open moulding, extrusion, pultru- sion and filament

winding.

It is further contemplated that the fibre or wires of metal

can be interwoven with non- resorbable polymers such as nylon fibre, carbon

fibre and polyethylene fibre, among others, to form a metal-polymer composite

weave. Further examples of suitable non- resorbable materials include DACRON

and GORE-TEX. The fibre may further be treated, for example, chemically or

mechanically etched and/or silanized, to enhance the bond between the fibre and

the polymeric matrix. The fibre preferably take the form of long, continuous

filaments, although the filaments may be as short as 0.1 to 4 millimeters.

Shorter fibre of uniform or random length might also be employed. The fibrous

element may take the form of a fabric. Fabric may be of the woven or non-woven

type and is preferably preembedded with a polymeric material as set forth

herein. The fibrous component may be present in the fiber reinforced composite

material in the range from about 20% to about 85%, and more preferably between

about 30% to about 65% by weight.

In an embodiment the first and/or second and/or third

polymeric component is nano- fibre and/or a nano-structured composite. The

nanofibre is nanofibre of any of the polymers mentioned elsewhere herein.

The composite polymeric material may be a nano-structured

composites in the form of reinforced polymers with low quantities (<25% eg.

less than 15% or less than 5%) of nano-metric sized clay particles or

nano-metric sized particles of any other material mentioned herein.

In an embodiment the first and/or second and/or third

polymeric component is cross- linked. The polymer is selected from any of the

polymers mentioned herein. The combination of a polymer having a high chain

length and a polymer having a shorter chain length, but being cross-linked

provides a strong device yet having the resilient properties necessary for the

device.

In an embodiment the first and the second polymeric

component comprises the same monomeric component or the same components of the

composite material. Optionally these polymeric components further comprise one

or more metal components, which may be of different length in the two polymeric

component.

The device and units may be designed not to interfere and to

be non-invasive with regards to intra-articular components when the device is

in the joint cavity by means such as a slit in the body of the device.

Moreover, non-interference of the intra-articular components may be achieved by

a hole which runs through the body of the device; that is to say the device may

comprise a hole through which intra-articular components may pass. When loading

the device, the slits may serve to pass intra-articular components through the

body of the device. The slits in this embodiment run from the periphery of the

body of the device to the hole through which the intra-articular components

pass after the device is implanted or loaded.

Typically, and to at least some extent, the device is

adapted in its structure and/or material composition to alleviate conditions

associated with worn cartilage by providing a spacer function and/or to exert

pressure distribution in the joint when the joint is loaded and/or to provide

at least part of the sliding/rotating movement of the joint by internal

movement of at least part of the device.

It is also an object of the present invention to provide a

method for non-invasive locking of a device within a joint. In addition, the

method may be independent of use of cement or bony ingrowth of the device.

A still further object of the present invention is to

provide a kit for use in the method for non-invasive locking of a device within

a joint.

It is also an object of the present invention to provide a

method for preventing damage between mating surfaces or articulating surfaces

within a joint such as between the femoral head and the acetabulum of a hip

joint.

A more specific object of the present invention relates to a

prosthetic device for insertion into a joint cavity of a joint of a vertebrate

such as a human, the device is being adapted to provide a spacer function

and/or to exert stress distribution in the joint when the joint is loaded

and/or to provide at least part of the sliding/rotating movement of the joint

by internal movement in the material of at least part of the device, the device

being capable of being fixed or retained in the joint cavity in a manner which

is substantially non-invasive with respect to cartilage and bone natively

present in the joint cavity. When inserted into the joint cavity the device can

be constructed to locking itself to an intra-articular component and thereby

being fixed or retained in the joint cavity.

Physical-Structural

Features of the Device

The physical-structural features of the device relate to the

size, form or shape of the device as well as the structural components and

design components of the device.

Size and Shape

The overall shape of the device is such that it

substantially fits into the excising anatomical dimensions of the joint. In

general, the size and shape of the device may be such that the device fits into

the intra-articular cavity in that it may partially or fully occupy the space

defined by the cavity, this depends on the type of device. For some of the

joints it is preferred that the extent of the device, when positioned in the

joint cavity, is larger than the normal extent of cartilage on the bone end in

that joint. In an embodiment, a hole runs through the body of the device to

allow intra-articular components to traverse the body of the device and thus be

surrounded by the device.

In this embodiment, the device may be construed in a liberal

sense as essentially torus-shaped in that the device can be of a plurality of

geometrical shapes, symmetrical and asymmetrical, comprising a hole which runs

through the body to create an internal tubular passage through which

intra-articular components may pass.

The device may also be ball-shaped, disc-shaped, spherical,

globular-shaped, cup- shaped, cone-shaped, ring-shaped, cylindrical and have

convex, concave, or flat surfaces. Accordingly, the body of the device shape

can e.g. be in the form of a horseshoe, a curl, ring-shaped, circular or

semicircular so as to be suitable for fitting into the anatomical dimensions of

the particular joint. Furthermore, the device may be asymmetrical.

The body of the device may be of a geometrical shape

comprising a surface having the form of body shaped by rotating a circle about

a coplanar axis which does not intersect the circle. It may be ball-shaped,

disc-shaped, globular-shaped, cup- shaped, cone-shaped, ring-shaped,

cylindrical and may comprise convex, concave, or flat surfaces. In some aspects

it is characterised in that it comprises a hole extending from one surface of

the body of the device to the same or another surface, creating an internal

tubular cylinder. This internal tubular cylinder may be straight if the hole

extended to two parallel surfaces, curved if the hole extends to perpendicular

surface, U-shaped if the hole extends to two parts of the same surface or a

combination of one or more of these internal shapes and thus tortuous.

Certainly, given that the overall shape of the device is

such that it substantially fits into the excising anatomical dimensions of the

joint, it is anticipated that the body of the device may be asymmetrical or of

no definable shape so as e.g. to the fill the intra-articular cavity, to allow

for the movement of the intra-articular components during the flexing of the

joint, to support intra-articular components or to support matter which form

the walls of the cavity.

It is preferable that the shape of the device is such that

it does not impede the normal functioning of the joint and its components.

It is particularly anticipated that the body of the device

may be asymmetrical or of no definable or uniform shape when the device is for

use in a hip joint. Alternatively, the shape of the device may be such that it

resembles the native cartilage, or part thereof, naturally present in the joint

cavity.

Accordingly,

in the case of a hip joint, the shape of the device is preferably such that it

fits into the existing space of the joint cavity comprising ligamentum capitis

femoris, the "walls" of the space being defined by the concave shape

of the acetabulum and by the convex shape of the femoral head.

Moreover, the overall shape of the device may be a result of

an assembly of more than one units of the device, such as the assembly of two

or more rings of different sizes stacked upon each other so as to form a

cone-shaped device. The assembly of units may be done in vivo or ex-vivo.

Furthermore, in an embodiment, the overall shape is such

that the device is capable of locking itself to an intra-articular component if

present in the joint and thereby being fixed or retained in the joint cavity.

When the intra-articular component is a ligament, the shape is such that the

ligament is surrounded or substantially surrounded by the device.

However, the overall shape of the device may have any other

form as long as the material is of such a character that the device when

present in situ fits into the joint cavity, for example due to elastical

deformation of the device.

Preferably, the elastical deformation of the device is such

that the presence of liga- mentum capitis femoris results in a shape leaving

room for the ligamentum. Otherwise, the surface of the upper part of the device

facing the acetabular cavity may comprise a groove embedding the ligament.

Typically, the shape of the device is formed from a moulding

of its materials or from a casting process. It may alternatively be the result

of a framed structural construction or skeletal assembly. It is typically solid

in that the body of the device is not hollow but rather such that the material

of the device comprises all or essentially all of the space between two

surfaces. The moulding, casting, construction or assembly may form a device

into a uniform or non-uniform shape.

The device is essentially uniform in its stiffness or

compressibility. However, when loaded, the material may have a tendency to

deform in such a way that the locking mechanism is altered. This may occur if

the element adapted to surround the ligament, when present in situ, has a slit

which expands or gapes upon loading when the device is pressed together. This

gaping may be further pronounced when the patient is e.g. walking whereby the

ceiling of the acetabulum is pressed down on the upper surface of the device

and the lower surface of the device is pressed down on the spherical surface of

the femoral head.

Due to the rolling movement (rotation within the joint) of

the femoral head, the possibility exists that the femoral head may press itself

up into the slit of the device during the movement. In such cases, the press

distribution and/or internal movement of the device may be limited to a minor

part of the device that may result in an undesirable increased pressure on that

portion of the device. Finally, contact between the femoral head and the

acetabulum may occur in case the femoral head penetrates through the device.

However, a device comprising parts overlapping each other can prevent this

possible undesirable effect.

Accordingly, as mentioned above, the device may be

curl-shaped whereby the de- vice with respect to the slit or opening has

overlapping parts which do not represent a complete opening in the loading

direction.

The size of the prosthetic device according to the invention

may be of any size corresponding to the dimensions of the joint. In a hip

joint, a suitable size is normally one that allows the diameter of the device

to be about the same or less than the diameter of the femoral head. However, on

some occasions the diameter may exceed that of the femoral head. The size may

also depend on the degree of damage of the native cartilage of the joint.

Moreover, the space available within the joint in the individual may have an

effect on the preferred diameter. Also the compressibility of the material

should be taken into account. In the case in which the material is highly

compressible, the device may increase in diameter upon loading of the joint;

when loaded, the device should generally cover the surface area which is

covered with cartilage in the normal joint, e.g., in the hip joint, the surface

of caput femoris should preferably be substantially covered when the joint is

loaded to avoid contact of the surface of the femoral head with the acetabulum.

The length of the diameter of the device is designed to fit

into the particular joint, such as between 1-80 mm, such as between 2-70 mm,

preferable between 10-60 mm, more preferable between 15-50 mm, most preferred

about 40 mm, when the joint is loaded.

The prosthetic device according to the invention may vary in

thickness depending on the load on the joint, and the thickness of the device

may also vary within the device.

The thickness of the device in each of the middle area and

outer area is at least 0.1 mm, preferably between 0.2-60 mm, such as between

0.3-40 mm, preferably 0.6-30 mm, more preferably about 0.8-20 mm, most

preferably about 1-15 mm in the unloaded stage. Depending on the material, the

device may be highly compressible, whereby the initial thickness may exceed the

above-mentioned upper limit. If only a limited rotation takes place in the

joint, the thickness of the device may be decreased.

In one embodiment of the invention, the device is capable of

locking itself to the in- tra-articular component by at least one element of

the device surrounding the component in such a manner that displacement of the

element, and thereby the device, is limited by interlocking with the component.

The intra-articular component which is surrounded is preferably a ligament,

such as a ligament natively existing in the joint cavity.

In one embodiment of the device according to the invention,

the element completely or substantially completely surrounds the ligament.

Thus, one embodiment relates to a prosthetic device

according to the invention re- lates to a device wherein the element

interlocking with a ligament, when present in situ, permits the ligament to

extend through the element and substantially exert its natural function on the

joint.

In one aspect of the invention, the prosthetic device is

intended for the articulation of a hip of a human, the device being adapted

such that when present in situ in the human hip joint cavity, it comprises at

least one element surrounding ligamentum capitis femoris. Accordingly,

ligamentum capitis femoris represents the surrounded intra-articular element

mentioned above.

It is contemplated that the surrounding of the intra-articular

component by the element may be a completely or substantially completely

encircling of the ligament.

It is also preferred that the prosthetic device, when

present in situ, comprises at least one ring-shaped or substantially

ring-shaped element.

According to another aspect of the invention, the element of

the prosthetic device which is adapted to surround the ligament when present in

situ has such a shape and such properties that it can be placed around the

ligament and stay interlocked with the ligament.

Structural Components

The device preferably comprises structural components which

permit arrangement of the body of the device around native intra-articular

components.

When the prosthetic device according to the invention is a

hip endoprothesis, the device has a shape and structural components permitting

arrangement of the body of the device around ligamentum capitis femoris.

A prosthetic device according to the invention comprises a

device wherein the element of the device interlocking with the device with an

intra-articular component has such a shape and/or properties that it is capable

of replacing or supplementing worn or damaged cartilage in the joint and/or is

capable of preventing wear of the native cartilage of the joint or of the bone

tissue of the joint.

The structure of the material of the device or of a part of

the device may be in the form of fibres and filaments of polymers and/or metal

which can be incorporated into the matrix in a braided, woven, spongy or spiral

pattern, the fibres and filaments having reinforcing properties. The polymer

fibres may be inorganic fibres such as carbide, nitride, boride, carbon and

oxide fibres, or the polymeric reinforcement may be of organic origin such as

Dacron™. In a preferred embodiment the fibres are selected from polyethylene

fibres, polypropylene fibres or a combination thereof. The metal may be any

suitable metal e.g. titanium, gold, silver and/or chromium- cobaltum, and may

be of any structure as described elsewhere herein.

The structure of the material of the device may comprise a

layered or laminated structure, a core of one material or one or more

interposed layers with different properties enabling an overall function of the

devise suitable for providing a spacer function and/or to exert pressure

distribution in the joint when the joint is loaded and/or to provide at least

part of the sliding/rotating movement of the joint by internal movement of the

device, or relevant part of the device. However, it is preferred that the

material itself does not comprise interposed layers resulting in sliding

between the layers and thereby tear on the mating surfaces within the device.

Accordingly, the body of the device should be one continuous solid or

semi-solid material. In one preferred embodiment of the invention, the device

comprises a tubular passage through which the ligament can pass and be

surrounded by the body of the device. Circular movement around the

substantially central ligament is possible but replacement of the device is

prevented. A further feature of the structure of the de- vice may be that of a

slit extending from the outer surface of the device and through the body of the

device into the central tubular passage. The slit may be curl-shaped in the

radial direction with the axis of the tubular passage being the centre.

The slit may curl or curve into the body of the device so as

to form an S-, or C- shaped slit, or zigzag or spiral slit. The curl of the

slit may be in the two dimensions of a disc shaped device, or may curl in all

three dimensions in the case of a globular, spherical, cone-shaped or

cup-shaped device.

Furthermore,

in embodiments where the device comprises more than one unit, the curvature of

the slit may be such as to form a zigzag, spiral or S- or C-shaped multi- unit

slit.

In multi-unit devices, the outer surfaces of the parts of

the unit which are in contact with each other may have a surface pattern

preventing the units from sliding apart such as grooves or etching or jagged

surface pattern.

Moreover, the overall shape of the device may be from an

assembly of two or more elements of one device, such as two semi-circular

elements assembled to form a ring or from the assembly of two elements

obtainable from the cross-sectioning of a ring or globular device along their

longest axis. As was the case for the surface of two units, two elements may

have a surface pattern preventing the elements from sliding apart such as

grooves or etching or jagged surface pattern. Thus, a device and its shape may

be the result of an assembly of two or more elements and/or two or more units,

each comprising surfaces designed to preventing slippage of units and/or

elements.

If suitable, the device may comprise a material which

functions as a frame for the shape or secures the device from opening when

placed in situ, for example in the form of a shaped component having the

properties of a spring or the like. In one embodiment, the ring-shaped body of

the device has a slit or other suitable means which enables the device to be

placed in the position encircling ligamentum capitis femoris.

Upon loading the device into the joint, the element of the

device surrounding the component, e.g. a ligament, and thereby interlocking

with the component, may tend to open up due to deformation of the device in the

form of flattening resulting in an increased diameter. When the diameter of the

device increases, e.g. the diameter of a ring-shaped device comprising a slit,

the adjoining surfaces of the slit may gape.

As stated, during the compression, extension or rotation of

the device when the device is present in a joint, the slit may have a tendency

to gape and thus result in reduced weight-bearing effectiveness and/or result

in trapping of intra-articular components within the seam of the slit.

Preferably, the seam cannot be pulled apart in the direction of the plane of

the seam by the mechanical pressure exerted by the body of the device conferred

by the elastic properties of the material.

To prevent undesired slippage of the seam perpendicular to

the plane of the seam, a variety of means may be incorporated into the design

of the device so as to lock or adhere the two sides of the seam. Preferably,

the locking or adherence means are reversible so as to allow removal or

manipulation of the device after initial loading and use.

The seam is preferably characterised in that a smooth

surface is formed in the plane of the seam.

To prevent the device from opening, the device preferably

comprises overlapping or intersecting parts, such as lips or dovetails as is

known by the person skilled in the art of mechanics or moulding. The two sides

of the seam may be adjoined by means of an interlocking device such as a

protrusion-hole device on sides of the seam. Alternatively, to prevent slippage

in perpendicular to the plane of the seam, each side of the seam may be such

that each side of the seam comprises an alternating sequence of angled grooves

and corresponding extrusions. Moreover, the top and bottom portion of each side

of the seam may comprise alternating teeth and sockets to prevent slippage. To

prevent gaping such overlapping parts and their mating sur- faces of the sides

of the seam may have an interlocking surface structure. The pattern of such a

structure may include depressions on the mating surface of one part and corresponding

elevations on the other mating part of the device.

Accordingly, in one embodiment, the overlapping parts are

such that the interlocking surface structures constitute grooves. These grooves

may extend radially, primarily resulting in a decreased tendency of the device

to "open up" at the area corresponding to the slit or the gap. The

grooves may also be orientated in a circulatory structure preventing the mating

surfaces from gliding or sliding apart from each other. Additionally, the structure

may comprise a combination of both elements reducing undesired movement in both