Invention (Patent): Castro FF, Fisher JMO, Moskovitz AP. Semi-constrained ball and socket joints. US20130013079A1 (2013).

US20130013079A1 US

Inventors: Floyd Franklin Castro, James Mark Oakley Fisher, Alex Paul Moskovitz

Current Assignee: CASTRO FLOYD

Worldwide applications 2012 US

Application US13/544,479 events:

2012-07-09 Application filed by Individual

2012-07-09 Priority to US13/544,479

2013-01-10 Publication of US20130013079A1

2014-09-10 Assigned to CASTRO, FLOYD

2015-06-23 Application granted

2015-06-23 Publication of US9060862B2

Status: Expired - Fee Related

2032-07-09 Anticipated expiration

Semi-constrained ball and socket

joints

Floyd Franklin Castro, James Mark Oakley Fisher, Alex

Paul Moskovitz

Abstract

Regarding

semi-constrained artificial ball (head) and socket (cup) joints such as the hip

or shoulder joint, which allow for certain numbers of degrees of rotation along

three independent axes. For example, one embodiment creates at least two axes

of rotation through a super-spherical space carved out of the inner surface of

the cup, with a cup-cable connecting two points along the super-spherical

space, and a perpendicular head-cable looping around the head and the cup-cable

within the super-spherical space, and with the head-cable residing in a groove.

Another embodiment creates two axes of rotation through a combination of a 1)

swivel with lever and/or 2) cable attached to a circular track (with the knob

or ring around cable facing inward or outward), both of which have the center of

the head as the center of rotation. The third axis may be created by a

horizontal swivel and by wiggle room.

Description

CROSS REFERENCE TO RELATED APPLICATIONS

This application claims the benefit of U.S. Provisional

Application No. 61/505,970, filed Jul. 8, 2011, of the same title and same

inventors.

BACKGROUND

Natural ball and socket joints (such as hip (FIG. 1) and

shoulder joints (FIG. 2)) allow for certain degrees of rotation along three

independent axes. For instance, you can kick your leg forward/backward,

outward/inward, and twist your leg. (The ball in that instance is the end of

the femur that fits inside the enclosing socket of the hip.) Older adults and

others in need of artificial ball and socket joints (such as hip and shoulder

replacements) wish to maximize range of movement without a high risk of

dislocation of the ball from the socket. Furthering this goal allows the

prosthetic bearer to, among other things, participate maximally in fitness that

can help prevent one's health from deteriorating, and also to avoid painful

corrective surgeries that further disrupt the ball and socket connection and

risk even further dislocation. Thus, there is an extremely substantial need for

a prosthetic apparatus that allows for maximal range of rotational movement

without dislocation.

There have been many attempts to constrain the ball to the

socket in the past: For instance, U.S. Pat. Nos. 7,780,737; 7,766,971;

7,749,277; 7,335,231; 7,192,449; 7,179,298; 7,179,296; 7,169,186; 7,160,332;

7,144,427; 7,115,145; 7,074,24; 7,022,142; 6,986,792; 6,923,833; 6,527,808;

6,299,647; 6,042,612; 6,042,611; 5,916,270; 5,782,930; 5,639,280; 5,556,434;

5,092,897; 5,062,823; 4,960,427; 4,770,661; 3,996,625; U.S. Applications

20100174380; 20100087930; 20080125866; 20090088853 20070225818; 20070135927;

20070106392; 20070106389; 20060241780; 20060101; 20030050703; 20030191537;

20030212458; 20010032021. However, all are limited either in rate of

dislocation or in range of smooth motion. Thus, this extremely substantial need

for a prosthetic ball and socket apparatus that allows for maximal range of

motion along each of the planes of rotation and along the line of twisting

without dislocation has gone unmet for quite some time.

SUMMARY

Versions of the invention allow for increased degrees of

rotation of a head-bone (such as a femur 112 or a humerus 402)

along three independent axes relative to the cup-bone (such as a hip-bone 102 or

a shoulder framework 404), while still constraining the head-bone from

dislocation from the cup-bone.

First, to explain some terms—imagine the head as an earth

viewed from space, with an equator, a north pole, south pole, northern

hemisphere, latitudinal lines (running sideways), longitudinal lines (running

north and south). Now imagine a head from the preferred embodiment from

the first version 108 inside a socket 104 of a

cup 106 (see FIG. 12). The head's north pole 1202 is

closest to the apex of the inner surface of the cup 702 (though when

the head 108 rotates, the head's north pole 1202 rotates).

The apex of the inner surface of the cup may also be referred to as “the north

pole of the inner surface of the cup.” The head's south pole 1204 is

furthest from the apex 702 of the inner surface of

the cup 802. The head's equator 1206 contacts where

the rim of the inner surface of the cup 532 meets

the head 108 through the cup-liner 531 (except when

the head 108 rotates). In neutral position (when

the head 108 has not articulated in any directions yet), the

cup's north pole 514 and equator 532 are at

approximately the same point as the head's north pole 1202 and

equator 1206 (this is not true when the head 108 has

rotated along either the line of a cup-cable 526 or perpendicularly

along the line of a head-cable 202). Usable head rotation means geometries

of various parts that when combined into an embodiment and/or version, allow

for head rotation that satisfies a particular function (walking default,

alternatively normal movement, or movement sufficient to do a particular

activity and/or other functions), and obviously does not break down after a

week of use (alternatively, nor does it lead to excess buildup of toxic

material, for example metal debris leaching out into the body resulting from

metal on metal rubbing). For instance, the term “horizontal” (usually used in

context of a “horizontal swivel”) means latitudinal enough for usable head

rotation (the term horizontal is defined alternately and more specifically

below).

FIGS. 1-12 all depict an embodiment (which is the

preferred embodiment of the first version and of all versions) of the first

version. This version comprises (see FIG. 5, and also FIG. 2 for

most parts) A) a head to head-bone rod 218 (with one end to be

inserted into the head-bone such as a femur 112 or

a humerus 402, and a second end connected to a head 108), B)

the head 108 and C) a cup 106 encircling

the head 108, with the cup 106 to be inserted into the

cup-bone (such as the hip-bone 102 or the shoulder framework 404),

and D) a cup-liner 531 interposed between the cup 106 and

the head 108.

For the first version:

A. The head to head-bone rod 218 fastens at one

end to “roughly the south pole of the head”, and at the other end comprises a

rod to be inserted into the head-bone. (See for example FIG. 2). [“Roughly

the south pole of the head” means close enough to the south pole of the head to

allow for usable head rotation.] Alternatively, the head to head-bone rod can

attach to the south pole (without the “roughly” qualification), or anything in

between roughly and exactly. If the head-cable 202 passes through

“about the head's south pole”, [“about the head's south pole” means close

enough to the south pole to allow for usable head rotation] then the head to

head-bone rod 218 has a hole roughly at the south pole end of

the head 1204 to allow the head-groove 204 and

head-cable 202 to pass through about the south pole 1204.

(See FIG. 9).

B. The head: The head 108 is “roughly a ball

shape” [meaning having spherical portions of the surface of the head 108 that

allow it to fit snugly within the spherical portions 506 of the

inner surface of the cup 802, even when the head 108 is

rotated along any axis allowed to any number of degrees allowed (in the context

of all of the parts put together), as well as having room for the

cup-cable 526 within the super-spherical cavity 804] that fits

inside the cup 106 and contacts the spherical

portions 506 of the inner surface of the cup 802 through

the cup-liner 531. “A head fitting inside the inner surface of the cup”

means the same thing as “roughly a ball shape”. The phrase “contacting the

spherical portion of the inner surface of the cup” contemplates direct contact

with the spherical portion of the inner surface of the cup and/or indirectly

through a cup-liner. Ideally, the head contacts all spherical portions of the

inner surface of the cup, but alternatively, the head contacts enough spherical

portions to allow for usable head rotation or more.

The head 108 has a “roughly longitudinal

groove” [meaning sufficiently longitudinal to allow for usable rotational

movement of the head 108 along the cup-cable 526 axis

in both directions and defined as a “head-groove” 204] looped around the

circumference of the head 108 running “roughly pole to pole”

[meaning both 1) going from the north pole of the head 1202 to

the south pole 1204 and back, and 2) changing direction in its

loop from northward to southward (and vice versa), closely enough to each pole

to allow for usable head rotation, including but not limited to rotational

movement of the head 108 along the cup-cable 526 axis

in both directions]. Alternatively, the head-groove may be completely

longitudinal and run completely pole to pole, or anything in between this

exactitude and that allowing for usable head rotation. The phrase “fitting

inside the head-groove when the head-cable is between the head and the

spherical portion of the inner surface of the cup” means that those portions of

the head-cable that are currently between the spherical portion of the inner

surface of the cup and the head are inside the head-groove so as not to get

caught or pinched between the head's spherical surface and the spherical

portion of the inner surface of the cup. Alternatively, the head-cable can be

“looping around a portion of the head”, where the head cannot move

translationally away from the inner surface of the cup's north pole without the

head-cable tightening, or catching. This serves the same purpose of

constraining the head translationally as when the head-cable is “attaching to

the head” at at least two ends.

Note that while ball-bearings 602 are included in

the preferred embodiment between the head 108 and the

head-cable 202, allowing the head 108 to rotate

independently of the head-cable 202, thus allowing the head-cable 202 to

maintain its shape when it loops around the cup-cable 526, thus obviating

the need for the head-cable 202 to be flexible, that if the

head-cable 202 is flexible, then it can change its shape as the

stretch of head-cable forming the loop around the cup-cable 526 changes.

(This change in shape can also allow the head 108 to potentially

rotate further than if the head-cable 202 was straight—see for

example FIG. 11D showing the head-cable line rotating further along

the head 108 than in the super-spherical cavity 804—see

also FIG. 16D.) Additionally, even if the head-cable 202 is not

flexible, and the head 108 did not rotate independently from the

head-cable 202, there would still be wiggle room before either an end of

the loop of the head-cable 108 hit the cup 106 or the

head-cable 108 caught on the cup-cable 526.

In another embodiment, a sheath 1304 encloses

the head-cable 202 for a portion of the head-cable 202 that

does not need to come out of the head-groove 204 to begin to loop

around the cup-cable 526 (optionally and preferably all of the length

not needing to come out of the groove) during usable head rotation

(see FIG. 13A).

In yet another embodiment (see FIGS. 15A-15B), the

swerving head-cable 1502 and/or swerving head groove 1506 in

the accommodating head 1504 do not go around the south

pole 1204 of the head 1504, though the swerving

head-cable 1502 does make a complete loop (no breaks in the swerving

head-cable 1502), obviating the need for a hole 570 between

the stem 110 and the south pole of the head 1204,

making the formerly pronged portion 564 into a

non-pronged portion 1306. Again, the geometry of the swerve around the

south pole of the head 1204 must 1) allow for usable head

rotation and 2) if no sheath (similar to the sheath 1304 in FIG.

13A) is used around the swerving head-cable 1502, not allow for the

swerving head-cable 1502 to slip out of the swerving head-groove 1506 during

usable head rotation.

In yet another embodiment (see FIG. 13B), the

head-cable 202 and/or head-groove 204 do not go all the way

down to the south pole of the head 1204 and loop around it, but

attach 1302 to the accommodating head 1308 at certain

latitudes above the south pole of the head 1204 at each end. The

latitudes at each end attached must allow for usable head rotation.

In yet another embodiment (see FIGS. 14A-14B), the

head-cable is forked 1406 (with accommodating forked

head-groove 1404) around the south pole of the head 1204, again

obviating the need for a hole 570 between the stem 110 and

the south pole 1204 of the head 1402, making the

formerly pronged portion 564 into a

non-pronged portion 1306. Again, the geometry of the swerve around

the south pole of the head 1204 must 1) allow for usable head

rotation and 2) if no sheath (similar to the sheath 1304 in FIG.

13A) is used around the forked head-cable 1406, not allow for the forked

head-cable 1406 to slip out of the forked head-groove 1404 during

usable head rotation.

In yet another embodiment (see FIGS. 16A-16B), instead

of one head-cable 202, a number one head-cable 1604 in a number

one head-groove 1606 is used on one side of the south pole of

the head 1204, and a number two head-cable 1608 in a number

two head-groove 1610 in an accommodating head 1602 is

used on the other side of the south pole of the head 1204, again

obviating the need for a hole 570 between the stem 110 and

the south pole of the head 1204, making the formerly

pronged portion 564 into a non-pronged portion 1306.

Again, the geometry of each head-cable around the south pole of

the head 1204 must 1) allow for usable head rotation and 2) if

no sheath (similar to the sheath 1304 in FIG. 13A) is used

around the number one head-cable 1604 or the number two

head-cable 1608, not allow for either head-cable to slip out of the

head-groove 1610 during usable head rotation. Note that any number of

head-cables may be used, so long as they allow for usable head rotation. It is

best (and optional) to have the head-cables parallel and close to the north

pole-south pole line of the head 1602, but they may be non-parallel

and/or further apart if they still allow for usable head rotation.

In yet another embodiment (see FIG. 17), the above

embodiment (in the previous paragraph) with multiple head-cables is changed by

replacing the cup-cable 526 with two mini-cup-cables 1702.

Again, the geometry must allow for usable head rotation. It is optionally

useful to have stretchable head-cables to obtain more degrees in the range of

motion along each axis.

In yet another embodiment (see FIG. 20), a shortened

head-cable 2004 does not have any head-groove 204 but

attaches to the accommodating head 2002 at two points 2006 in

the northern hemisphere of the accommodating head 2002, again

obviating the need for a hole 570 between the stem 110 and

the south pole of the head 1204, making the formerly pronged

portion 564 into a non-pronged portion 1306. Optimally, the

shortened head-cable 2004 attaches at each end at 45 degrees from the

north pole of the head 1202 on opposite sides of the north pole,

so as to allow the head 2002 to rotate 45 degrees in each

direction along the line of the shortened head-cable 2004 before

either 1) the attachment point 2006 of the head-cable 2004 bangs

into the inner surface of the cup 804, or 2) the shortened

head-cable 2004 catches on the cup-cable 526.

In yet another embodiment (see FIG. 2106), instead of

using a head-cable 202 and cup-cable 526, a head-cup-cable 2104 connects

the inner surface of the cup 802 to the accommodating

head 2102 with attachment point 2106 (optionally and

preferably connecting the north pole of the head to the north pole of the cup,

for maximum range of motion in all directions). It is useful for the

head-cup-cable 2104 to be stretchable and have room to unfold itself

and become longer (like a snake uncurling), so as to increase the range of

motion, so long as it does not get tangled within itself.

Note again that the above embodiments not needing

a hole 570 for the head-cable 202 have

an un-pronged portion 1306 attaching the stem to the south pole

of the head 1204. All of these embodiments optionally but optimally

have cables parallel to the north-south pole line and as close to it as

possible (excepting for a strong enough stem for usable head rotation).

If it is not necessary for the head-cable to slide linearly relative

to a head-groove, then the head-cable must just fit these requirements: 1) it

must be able to loop around the cup-cable(s) during usable head rotation; 2) it

must not catch at the cup's equator between the head and the inner surface of

the cup (through the cup-liner).)

Though not optimal, it is not necessary for the head-cable

to be in the head-groove all of the way along the head (aside from looping

around the cup-cable), so long as usable head rotation is obtained.

Though the cup 106 is shown in the figures

extending to the equator of the head and no further, the cup can extend down

beyond the equator of the head into the southern hemisphere, so long as usable

head rotation is obtained. This can be used as an additional safeguard to keep

the head from dislocating from the socket, but sacrifices range of motion to

the extent it encircles the head.

B. The cup: The cup 106 is comprised of

an inner surface 802 and an outer surface 511,

the outer surface 511 fastened to the cup bone (for

example, hip bone 102 or shoulder framework fitting around the

cup 404) and the head 108 fitting within the

cup's inner surface 802. The inner surface is comprised of

a spherical portion 506 and a super-spherical (hollowed out

beyond spherically) portion 508. (See for example FIG.

5 for components mentioned in this paragraph).

Optionally and preferably the super-spherical

portion 508 of the inner surface of the cup 802 viewed

from the side is a portion of a circle with its center the same as

the spherical portion 506 but with a larger radius, also

optionally with sides that jut inward allowing the cup-cable 526 to

contact the inner surface of the cup 802 at a perpendicular

angle. However, so long as the super-spherical cavity 804 allows

room for the head-cable 202 to loop around the cup-cable 526 and

rotate for usable rotation, there is enough concavity in the super-spherical

cavity 804.

Spherical Portion:

The spherical portion 506 of the inner

surface of the cup 802 “runs roughly all of the way around the

inner surface of the cup along latitude lines, is located roughly closer to the

cup's equator than the super-spherical portion, and extends approximately up

from the equator to a certain latitude on the inner surface of the cup”

[meaning also covering enough surface area along the head's equator 1206 to

accomplish the following: 1) once fitted into the spherical portion 506 of

the socket/cup, the head 108 cannot move translationally further

into the socket; and 2) the surface area of the portion where

the head 108 contacts the cup-liner 531 is sufficient

such that any debris buildup caused by rubbing of the head 108 and

the inner surface of the cup 802 against the cup

liner 531 does not unduly impair operation of the apparatus nor the

patient's health to render the hip implant unsafe to implant]. Alternatively,

the “inner surface wherein a portion of the inner surface running from the

cup's equator to a more northerly latitude” is defined to runs all of the way

around the inner surface of the cup along latitude lines, extends upward from

the cup's equator to a particular latitude (for example, 5, 10, 20, 45 degrees upward

from the cup's equator, these examples not meant to be limiting).

Super-Spherical Portion:

The super-spherical portion 508 of the inner

surface of the cup 802 “runs roughly all of the way around the

cup along latitude lines, is located roughly closer to the cup's north pole,

and extends down approximately from the inner surface of the cup's north pole

to said certain latitude on the inner surface of the cup” [meaning also

covering enough surface area to allow usable rotational movement both along the

line of the cup-cable 526 and along the line of the head-cable 202].

Alternatively, there can be “a portion of the inner surface running from the

more northerly latitude to the north pole of the cup”, wherein the

super-spherical (same meaning as “hollowed out super-spherically”) portion runs

all of the way around the cup along latitude lines, and runs down latitudinally

from the north pole of the inner surface of the cup to the latitude at which

the spherical portion begins.

Connecting the Cup to the Cup-Bone:

The cup 106 is fastened to the cup-bone,

either directly or indirectly through a mounting plate 302 (or other

combination of parts) encapsulating the cup 106 (optionally and

preferably with two screws into the cup-bone, and the cup 106 connecting

to the mounting plate 302 through male and female locking

grooves).

In yet another embodiment (See FIGS. 22A-C), the

portions of the cup 106 along the cup's equator are recessed

along the line of the head-cable 202 (with one recess 2202 at

one side, and another recess 2204 on the opposite side), allowing

the stem 110 room to swing up beyond 180 degrees (see FIG.

22B). Note that the cup-liner 531 must also be similarly recessed.

Optionally, the cup liner 531 lines at least

the spherical portions 506 of the inner surface of

the cup 802 and contacts the inner surface of the cup 802 on

one side and the head on the other side. (See for example FIGS. 3, 5).

Optionally, a locking ring for the cup liner holds the cup

liner in place, such as found in U.S. Pat. No. 7,766,971.

The cup-cable 526 runs “roughly parallel to the

surface of the head above the north hemisphere and roughly perpendicular to the

head-groove” [meaning parallel enough to the surface of the head and

perpendicular enough relative to the head-groove to allow for usable head

rotation], attached at each end at a point on the super-spherical portion of

the inner surface of the cup (optionally with a lip that allows the cup-cable

to contact the inner surface of the cup at a perpendicular angle). (See for

example, FIGS. 13A-B). Alternatively, the cup-cable can run exactly

parallel to the surface of the head above the north hemisphere.

Cup-Cable/Head-Cable Interface:

In yet another embodiment (see FIGS. 18-19), the

head-cable 202 can slide linearly relative to an interface 1802,

while the cup-cable 526 can also slide linearly (though perpendicular

to the head-cable) relative to the interface 1802. This allows the

distance between the cup-cable 526 and the head-cable 202 to

remain fixed for easier motion. The interface 1802 is composed

of 1) a subunit 1804 with a hole 1808 for the

head-cable 202 housing a roller bearing above the head-cable 1902 and

a roller bearing below the head-cable 1904; and 2) a subunit 1806 with

a hole 1810 for the cup-cable 526 housing a roller

bearing above the cup-cable 1906 and a roller bearing below the

cup-cable 1908. Note that any number of roller bearings (or other bearings

such as ball-bearings, or sets of bearings) may be used, so long as the

head-cable 202 and cup-cable 526 each can slide

independently. It is also possible to have only the cup-cable 526 able

to slide if ball-bearings in the head-groove allow the head to rotate

independently of the head-cable.

More on the Swivel:

The swivel allows the head-bone to rotate along the z-axis

(when you twist your leg (for the hip joint) or twist your shoulder (for the

shoulder joint) in the axis pointing from the inner surface of the cup's north

pole down to the head-bone, discussed earlier as “latitudinally”). Rotation

along this z-axis is called “horizontal”, resulting in the term “horizontal

swivel.” The swivel may be horizontal, or roughly horizontal enough to allow

for usable head rotation, or anything in between. The swivel may be at any

workable point between the head-bone and the cup-bone—thus, if it does not

interfere with the functioning of the other parts of the apparatus, such points

which should be obvious to one of ordinary skill in the art. For instance, the

swivel also may be between the inner surface of the cup 802 and

the cup-bone (for example, the hip bone 102 or the shoulder

framework 404), or between the inner surface of the cup 802 and

the head 108, or between the south 1204 pole of the head

and the head-bone (for example, the femur 112 or the humerus 402),

or bisecting the head 108 (so long as it doesn't interfere with the

head-cable 202 sliding in any head-grooves 204, and is

sufficiently strong so that the part adjacent to the swivel closer to the

cup-bone (for example, the hip bone 102 or the shoulder

framework 404) remains “substantially fixed” [meaning not susceptible to

breakage or unusable bending] (aside from the horizontal twisting afforded by

the swivel) relative to the part adjacent to the swivel further from the

cup-bone (for example, the hip bone 102 or the shoulder

framework 404)). The swivel is optional, as the head 108 may

still swivel horizontally before the head-cable 202 runs into the

cup-cable by becoming less perpendicular to each other.

It should be obvious to one of ordinary skill in the art,

using the main concepts and the first version to work off of, to make and use

different versions using a) various means of connection (instead of screws,

substituting other ways of connecting the parts); b) splitting a given part

into multiple parts (for instance, to allow for assembly of most parts outside

of the body, and to allow parts to be more easily replaced (for instance, so

the bone doesn't have to be drilled into)), and/or combining parts; c) varying

numbers along ranges (for instance, the size of the head, exact shape of

super-spherical cavity so long as it performs its function, exact latitude at

which the inner surface of the cup shifts from super-spherical to spherical,

exact placement and design of the horizontal swivel, among others); and/or d)

omitting features so long as the function of usable head rotation is still

served. While different type heads (or other parts) are referred to throughout,

the usage of a specific reference numeral (such as 108) is not meant to

constrain the meaning if other geometries (including but not limited to parts

from other embodiments and/or other versions) are workable within the general

inventive concept, but just to be an example.

It should be obvious to a person of ordinary skill in the

art how to assemble any of the previously mentioned versions, with the

following additional tips:

1. To assemble the head 108/head-cable 202/head

to head-bone rod 218 complex when there is a south pole hole in the

end of the head to head-bone rod 570 which the head-cable 202 and

head-groove 204 fit through, the head to head-bone rod 218 may

have two prongs 571 that fit into the head 108 at

the south pole of the head 1204, where the head-cable 202 loops

around the beginnings of the prongs in the prongs hole 570 and

turns along with the prongs 571 until the prongs 571 are

fully screwed in. (One alternative (not in preferred embodiment) would be if

the head-groove 204 is to completely loop around the south pole of

the head 1204, then after the head-cable 202 is inserted

between the two prongs 571, then a piece with head-groove

portion 577 facing the beginnings of the prongs 571 could

be attached between the two prongs to complete the head-groove 204 between

the prongs 571.) Or, instead of looping the head-cable 202 around prongs 571 in

the head-head-bone rod 218 before the prongs 571 are

screwed into the head 108, a section of one of the prongs 571 could

be cut out and replaced (or just put in) after sliding the head-cable 202 between

the two prongs 571. There are many other methods of assembling these

parts, which should be obvious to one of ordinary skill in the art.

2. To loop the head-cable 202 around the cup-cable 526 while

both will eventually end up in a covered cavity 804 between the

inner surface of the cup 802 and the northern hemisphere of the

head, there must be a hole adequate to allow the cup-cable 526 to be

inserted properly between the head-cable 202 and the head 108 (if

the preferred embodiment method detailed above of squeezing the cup-cable 526 between

two parts of the cup 106 is not used)—with (see FIG. 8B)

a hole 808 at either end of where the cup-cable 526 attaches

with an accommodating cup 810 to the cup, or (see FIG. 8C)

closer to the top of the cup, beginning with an accommodating cup 812 with

an accommodating hole in the top 814 through which first the

cup-cable 526 fits into the cavity 804 and then

the hole 814 is closed by an accommodating piece 816 to

fit into the cup 812.

Any number of variations of the above two methods of

assembly, and/or other methods, should be obvious to one of ordinary skill in

the art.

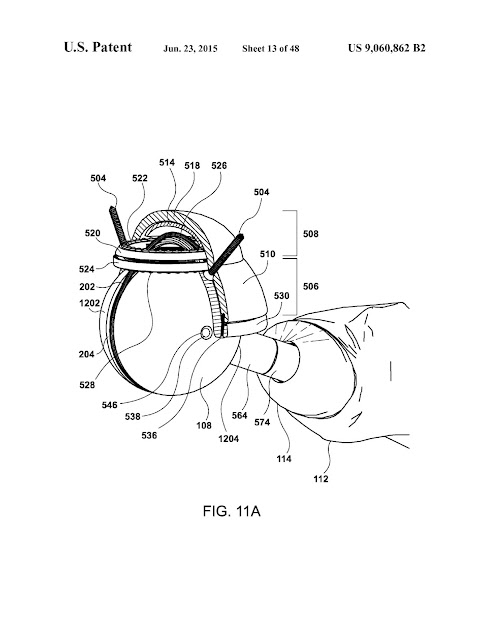

Each version may be used to create independent axes of rotational

movement (through a combination of rotation along the line of the

head-cable 202 (see FIGS. 11A-11B examples), along the line

of the cup-cable 526 (see FIGS. 11C-11D), and twisting through

the swivel—alternately using the natural twisting allowed by the head-cable and

cup-cable instead of the swivel), while still constraining the head

translationally relative to the cup. The degrees of rotation along each axis

are limited by physical constraints—ie when one part (such as a

head-cable 202) runs into another part (such as the inner surface of the

cup 802).

In another version, each axis of rotation is created

piecemeal through “swivel devices” that form a device assembly (which connects

the cup-bone (such as the hip bone 102 or the shoulder

framework 404) to the head-bone (such as the femur 112 or

the humerus 402).

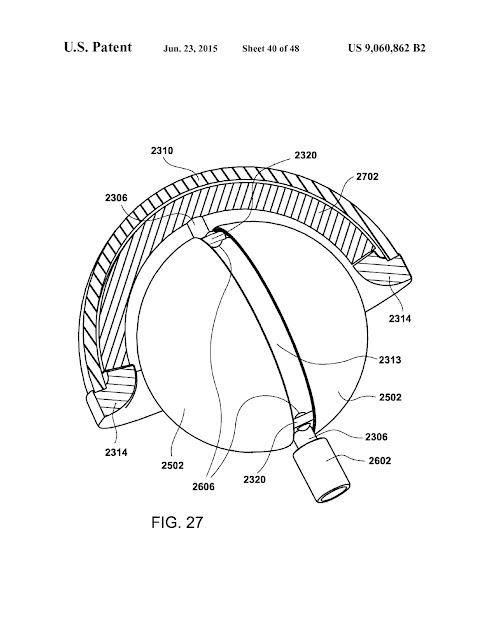

Each axis of rotation is created piecemeal through a “swivel

device” that rotates around where the center of the head 108 would

be, either through 1) a swivel with a lever (see for example FIGS. 30A-C),

comprising a swivel whose axis of rotation crosses through the center of the

head with a lever 3004 extending perpendicular to said axis of

rotation and outward from the center of where the head 108 would

be, or 2) a cable that is caught within but slides smoothly along a circular

track along a fixed radius from the center of the head (optionally with ball

bearings interfacing between the cable caught in the track and the track), the

cable being a permutation of the variables a) inside the head track (top left

of FIGS. 26, 29) vs. along the cup track (top left of FIGS.

27, 28) and b) type of track (for instance, knob inside track (top left

of FIGS. 26, 27) or ring around cable (top left of FIGS.

29, 28)). To create two independent axes of rotation, the axis about which

each device rotates is perpendicular to the other device's axis. Note that each

device may be attached to separate sides of the head (see for

example FIGS. 24A-24B, 31A-31B), or to each other (see for example

top left of FIG. 25A)—the only constraint when selecting devices is that

the lever device (see for example FIGS. 30A-30C) may only be used when

pointing outward from the head's center. Each device or combination (when the

devices are not on separate sides of the head but are connected to each other)

of devices attaches the head to either the head-bone or to the cup-bone, and

the connection between the head and the bone not connected by a combination

(the cup-bone or the head-bone, if two separate devices are not used) does not

have to rotate (but may, such as through another device).

Adding more devices even after two axes of rotation were

already created may be used to get extra degrees of rotation (such as by having

both the head-bone and the cup-bone each separately attached to cables that

insert along the same track (along the same axis of rotation, allowing for

possibly more than 180 degrees of rotation along that axis)). (For example,

see FIGS. 25A-C, where two knobs are both in a track 2313 in

the head).

Swivel with Lever:

FIGS. 30A-30C depict the preferred embodiment of a

swivel with lever 3004 (see FIGS. 30B-30C for inner parts).

An accommodating head 3006 (with optional fixed point 3008 on

opposite side of head 3006) is adapted to fit a swivel

with lever 3004 extending perpendicular to axis of rotation and

outward from the center of the head 3006, the swivel comprising

the lever 3004 which is rotated by a ring 3002 that

rotates about the center portion 3012 attached

the head 3006 through ball-bearings 3014.

The accommodating head 3006 contains a slot so that

the lever 3004 can rotate a certain number of degrees without

being stopped by the accommodating head 3006.

Inside Track:

An inside track is where something is caught within but

slides smoothly along a circular track along a fixed radius from the center of

the head, and where the fixed point is further away from the center of the head

(for instance on the cup) than the track. For example, 1) (see for

example, FIG. 27) a dumbbell portion with knob 2320 in track 2313 and stick

portion 2306 extending to fixed points at the cup 2702 and

on the bottom 2504 (optionally with ball-bearings 2704)

(see FIG. 27, two knobs 2320) the inside of the head 2502 or

2) (see for example, FIG. 29) a ring 2904 around

a cable 2906 in a slot 2902 on the inside of the

head 2908.

Outside Track:

An outside track is where something is caught within but

slides smoothly along a circular track along a fixed radius from the center of

the head, and where the fixed point is closer to the center of the head (for

instance in the head). For example, 1) (see for example, FIG. 26) a

dumbbell portion with knob 2308 in track 2312 and stick

portion 2306 extending down towards the center of the accommodating

head 2604 (optionally with ball-bearings 2606 and with

optional fixed point 2602 on the other side of accommodating

head 2604) or 2) (see, for example, see FIG. 28) a ring 2804 around

a cable 526 in a slot 2806 on

the accommodating cup 2808.

A horizontal swivel (with an axis perpendicular to that of

the two devices) may be created just as in the cables version (see for

example FIG. 28). Unlike some of the cables embodiments, a swivel

bisecting the head will not interfere with the operation of any cable, because

there is none.

As with the cables version, there are many ways of

implementing the details of the piecemeal version, such as number of parts

(such as more sets of ball-bearings for lever), type of parts (such as using

roller-bearings instead of ball-bearings), geometry (does not have to be exact

so long as the function of usable head rotation is fulfilled) and any other

factor obvious to one of ordinary skill in the art.

Alternatively to the piecemeal version, two or three axes of

rotation may be created through a gimbal for each axis of rotation (optionally

with a flexible cover). (For example, see FIG. 32). The third axis is

created through a horizontal swivel as above.

Additionally, one track combined with a horizontal swivel

may create two axes of rotation by acting like a weathervane (for example,

see FIGS. 23A-23B). For example, an outside track with a knob

(see FIGS. 23A-23B) can rotate along one axis. If the pressure on the left

side of the head is different from that on the right side of

the head 2304, then the head 2304 will swivel more and

more until it reaches the point where it is only rotating about the axis of

the track 2312.

Assembly of the piecemeal and track versions should be

obvious to one of ordinary skill in the art.

The materials used for each embodiment within each version

are those commonly used for making artificial hip joints. The inventor has no

preference.

So long as usable head rotation can be maintained without a

certain feature within a combination of features, that feature is optional. Of

course, parts of different versions may be combined when they produce usable

head rotation. Again, all embodiments mentioned above are merely intended to be

examples, and are not intended to limit the scope of the invention—one of

ordinary skill in the art will know many variations on implementing the details

without varying the inventive concepts.

BRIEF DESCRIPTION OF THE DRAWINGS

The accompanying drawings, which are incorporated in and

form a part of the specification, illustrate preferred (but not necessarily

necessary) embodiments of the present invention and, together with the description

and summary, disclose principles of the invention. Note: not all features of an

embodiment and/or version are necessarily present in one drawing.

FIG. 1 is a perspective view of an embodiment of the

invention connecting a femur to a hip bone.

FIG. 2 is a partially exploded view of an embodiment of

the invention with a head-cable.

FIG. 3A is a perspective exploded view of a hip bone,

an embodiment of cup liner and of cup.

FIG. 3B is a perspective partially exploded view of the

embodiment of FIG. 3A.

FIG. 3C is a unexploded perspective view of the

embodiment of FIG. 3A.

FIG. 4A is a perspective view of an embodiment of the

invention forming the glenohumeral joint.

FIG. 4B is a perspective view of the embodiment

of FIG. 4A, but with the glenohumeral joint magnified.

FIG. 5 is a perspective, exploded, partial cross

section view of an embodiment with head-cable.

FIG. 6 is a perspective, exploded view of the

embodiment of FIG. 5.

FIG. 7 is a perspective, partial cross section view of

the embodiment of FIG. 5.

FIG. 8A is a cross section view of an embodiment of the

cup.

FIG. 8B is a perspective view of a first method of the

cup-cable being assembled into an embodiment of the cup.

FIG. 8C is a perspective view of a second method of the

cup-cable being assembled into an embodiment of the cup.

FIG. 9 is a perspective partial cross section view of

the embodiment of FIG. 5.

FIG. 10 is a partially exploded, partial cross section

view of the embodiment of FIG. 5.

FIG. 11A is a perspective, partial cross section view

of the embodiment of FIG. 5 with the head rotated along the line of

the head-cable.

FIG. 11B is a different perspective view of the

embodiment of FIG. 5 with the head rotated along the line of the

head-cable.

FIG. 11C is a perspective, partial cross section view

of the embodiment of FIG. 5 with the head rotated along the line of

the head-cable and rotated along the line of the cup-cable.

FIG. 11D is a different perspective, partial cross

section of the embodiment of FIG. 5 with the head rotated along the

line of the head-cable and rotated along the line of the cup-cable.

FIG. 12A is a perspective, partial cross section view

of the embodiment of FIG. 5.

FIG. 12B is a side view, partial cross section of the

embodiment of FIG. 5.

FIG. 13A is a perspective partial cross section view of

an embodiment with a retaining sheath around the head-cable.

FIG. 13B is a perspective partial cross section view of

an embodiment with the head-cable attaching to the head at each end of the

head-cable.

FIG. 14A is a perspective, partial cross section view

of an embodiment with a forked cable around the south pole of the head.

FIG. 14B is a different perspective, partial cross

section view of the embodiment of FIG. 14A.

FIG. 15A is a perspective, partial cross section view

of an embodiment with a cable detouring around the south pole of the head.

FIG. 15B is a different perspective, partial cross

section view of the embodiment of FIG. 15A.

FIG. 16A is a perspective, partial cross section view

of an embodiment with two head-cables.

FIG. 16B is a different perspective, partial cross

section view of the embodiment of FIG. 16A.

FIG. 17 is a perspective, partial cross section view of

an embodiment with two head-cables, each of which loops around a separate

cup-cable.

FIG. 18A is a perspective view of an interface (and

surrounding parts) allowing the cup-cable and the head-cable each to slide

along each cable's respective line relative to the interface.

FIG. 18B is a different perspective view of the

embodiment of FIG. 18A.

FIG. 19A is a perspective view of the embodiment

of FIG. 18A, zoomed in relative to FIGS. 18A-B.

FIG. 19B is a perspective, partial cross section view

of the embodiment of FIG. 18A, zoomed in relative to FIGS. 18A-B.

FIG. 20 is a perspective, partial cross section view of

an embodiment where the head-cable attaches at each of its two ends at some

point along the northern hemisphere of the head.

FIG. 21 is a perspective, partial cross section view of

an embodiment where the head-cable attaches from the north pole of the cup to

the north pole of the head.

FIG. 22A is a perspective, partial cross section view

of the embodiment in FIG. 5 with a recess in the cup at each end

along the line of the head-cable.

FIG. 22B is a perspective, partial cross section view

of the embodiment in FIG. 22A with head and other parts added.

FIG. 22C is a perspective, partial cross section view

of the embodiment in FIG. 22A with head and other parts added and

head articulated.

FIG. 23A is a perspective, partial cross section view

of an embodiment with an outside track with knob, also with horizontal swivel.

FIG. 23B is a perspective, partial cross section view

of the embodiment of FIG. 23A with head articulated.

FIG. 24A is a perspective view of an embodiment of two

perpendicular inside tracks with knobs on opposite sides of the head and a

swivel in between.

FIG. 24B is a different perspective view of the

embodiment of FIG. 24A.

FIG. 25A is a perspective view of an embodiment with

one outside track with knob, combined with two parallel inside tracks with

knobs.

FIG. 25B is a different perspective view of the

embodiment of FIG. 25A with the head rotated along various lines.

FIG. 25C is a different perspective view of the

embodiment of FIG. 25A.

FIG. 26 is a perspective, partial cross section view of

an embodiment with one outside track with knob.

FIG. 27 is a perspective, partial cross section view of

an embodiment with two inside tracks with knob.

FIG. 28 is a perspective, partial cross section view of

an embodiment with an outside track with ring around cable with a horizontal

swivel.

FIG. 29 is a perspective, partial cross section view of

an embodiment with one inside track with ring around cable.

FIG. 30A is a perspective view of an embodiment with

swivel with lever attached extending from center.

FIG. 30B is a perspective, partial cross section view

of the embodiment of FIG. 30A with the head articulated.

FIG. 30C is a perspective partially exploded view of

the embodiment of FIG. 30A.

FIG. 31A is a perspective, partial cross section view

of an embodiment with an outside track with ring around cable with horizontal

swivel and swivel with lever attached extending from center on the opposite

side of the head.

FIG. 31B is a perspective, partial cross section view

of the embodiment of FIG. 31A with the head articulated.

FIG. 32A is a perspective view of an embodiment with a

gimbal attached to a horizontal swivel.

FIG. 32B is a different perspective view of the embodiment of FIG. 32A.

DETAILED DESCRIPTION

Versions of the invention allow for increased degrees of

rotation of a head-bone along three independent axes relative to the cup-bone,

while still constraining the head-bone from dislocation from the cup-bone.

First, to explain some terms—imagine the head as an earth

viewed from space, with an equator, a north pole, south pole, northern

hemisphere, latitudinal lines (running sideways), longitudinal lines (running

north and south). Now imagine a head from the preferred embodiment from

the first version 108 inside a socket 104 of a cup 106 (see FIG.

12). The head's north pole 1202 is closest to the apex of the

inner surface of the cup 702 (though when the head 108 rotates,

the head's north pole 1202 rotates). The apex of the inner

surface of the cup may also be referred to as “the north pole of the inner

surface of the cup.” The head's south pole 1204 is furthest from

the apex 702 of the inner surface of the cup 802. The

head's equator 1206 contacts where the rim of the inner surface

of the cup 532 meets the head 108 through the

cup-liner 531 (except when the head 108 rotates). In

neutral position (when the head 108 has not articulated in any

directions yet), the cup's north pole 514 and equator 532 are

at approximately the same point as the head's north pole 1202 and

equator 1206 (this is not true when the head 108 has

rotated along either the line of a cup-cable 526 or perpendicularly

along the line of a head-cable 202). Usable head rotation means geometries

of various parts that when combined into an embodiment and/or version, allow

for head rotation that satisfies a particular function (walking default,

alternatively normal movement, or movement sufficient to do a particular

activity and/or other functions), and obviously does not break down after a

week of use (alternatively, nor does it lead to excess buildup of toxic

material, for example metal debris leaching out into the body resulting from

metal on metal rubbing). For instance, the term “horizontal” (usually used in

context of a “horizontal swivel”) means latitudinal enough for usable head

rotation (the term horizontal is defined alternately and more specifically

below).

Cables Version

Versions of the invention allow for increased degrees of

rotation of a head-bone along three independent axes relative to the cup-bone,

while still constraining the head-bone from dislocation from the cup-bone.

Cables Version:

FIGS. 1-12 all depict an embodiment (which is the

preferred embodiment) of the first version. This version comprises

(see FIG. 5, and also FIG. 2 for most parts) A) a head to

head-bone rod 218 (with one end to be inserted into the head-bone

such as a femur 112 or a humerus 402, and a second end

connected to a head 108), B) the head 108 and C)

a cup 106 encircling the head 108, with

the cup 106 to be inserted into the cup-bone (such as the

hip-bone 102 or the shoulder framework 404), and D) a

cup-liner 531 interposed between the cup 106 and

the head 108.

A. The head to head-bone rod 218 is comprised of

i) a stem 110, the stem 110 at one end connecting to

a head 108, and at a second end connecting to ii) a head-bone

rod 114, said head-bone rod 114 to be inserted into the

head-bone (such as a femur 112 or a humerus 402). i)

The stem 110 is comprised of a) a pronged portion of

the stem 564, said pronged portion of the stem comprising a hole at

the non-pronged end 576 for insertion of a pronged-non-pronged

threaded portion of the non-pronged portion of the stem 572,

two parallel prongs 571 with a hole between

the prongs 570, and two holes for two countersunk screws 568 (to

go through the head 108), and b) a non-pronged portion 574,

comprised of a pronged-non-pronged threaded section 572, and a

head-bone connecting threaded section 574 with threads 575,

said head-bone connecting threaded section 574 having

a hole 578 for insertion of a head-bone connecting screw 214 connecting

said section 574 to the head-bone rod 114 and the

head-bone (such as a femur 112 or a humerus 402). ii) The

head-bone rod 114 is comprised of a male portion to be inserted into

the middle of the head-bone (such as a femur 112 or a

humerus 402), a lip, a hole in the lip 212 for said head

bone connecting screw 214 (connecting threaded section of head-bone

connecting threaded section of stem 574 to the head-bone

rod 114 and the head-bone (such as a femur 112 or a

humerus 404)), and a female portion 216 for insertion of

the threaded portion 575 of the non-pronged portion 574 of

the stem 110.

B. The head 108 is comprised of i)

a left semi-hemisphere 542 connected to ii) a central

portion 556 with a groove, ball bearings around the groove 602,

a sheath around the ball-bearings 204, and a head-cable around

the sheath 202, said central portion 556 connected to

iii) a right semi-hemisphere 544. i) The left

semi-hemisphere 542 contains a slot 546 for the

first countersunk screw 538 connecting the two semi-hemispheres,

a slot 547 for the second screw 540 connecting

the two semi-hemispheres, and slot 554 for one of the prongs of

the stem 571. ii) The central portion 556 has

two slots 558 for the countersunk screws. iii) The right

semi-hemisphere 544 has a first slot 548 and

a second slot 550 for the countersunk screws, and

a slot 547 for one of the prongs of the stem 571.

The head 108 has a north pole 1202, a south

pole 1204, and an equator 1206.

C. The cup 106 comprises i) an outer

shell 502 ii) a middle shell 517 and iii)

an inner shell 530.

i. The outer shell 502 comprises

a spherical portion 506 closest to the outer

shell's equator 516 and moving up to a certain latitude on

the head 108 where the outer shell is hollowed out beyond

spherically (where the radius is larger), called the super-spherical portion of

the outer shell 508. The outer shell helps enclose

the super-spherical cavity 804. Note the north pole of the inner

surface of the outer shell 514. Note that the outer shell 510 juts

inward at the lower ends so that the inner surface of the cup 802 is

perpendicular to the cup-cable 526 when meeting the cup-cable's 526 ends

(this can help prevent the head-cable 202 from getting caught between

the cup-cable and the inner surface of the cup 802). The outer shell is

connected to the head-bone, such as the hip bone 102 or

the shoulder framework 404 by two screws 504. The

outer shell is connected to the inner shell by two screws 536 that

fit into two slots in the outer shell 906.

ii. The middle shell 517 comprises a) a

mid-super-spherical inner shell 518 that fits inside the inner

surface of the outer shell and shaped 902 to fit the

ball-bearings 522 between it and a middle ring like portion 520 (with

a north pole on its inside surface 702); b) a mid-middle ring

like portion 520 shaped to fit the ball bearings 522 between

it and the mid-super-spherical shell 518, with notches on the bottom 604 to

trap a cup-cable 526 between the mid-middle ring

like portion 520 and a mid-lower shell 524; c)

a mid-lower shell 524 comprises a ring like portion with notches

on top to fit the cup-cable 526 between it and the mid-middle ring

like portion 520.

iii. The inner shell 530 has spherical

portions 506 but a hole cut out from the top to fit the

mid-super-spherical inner shell 518. The inner shell 530 encircles

the cup-liner 531, and both have a lip 534 so that

the outer shell 502 can rest upon the inner shell 530.

The outer shell is connected to the inner shell by two screws 536 that

fit into two slots in the inner shell 904.

Note that the inner surface of the cup 802 has

both a spherical portion 506 and a super-spherical

portion 508.

D. The cup-liner 531 is interposed between

the cup 106 and the head 108, but does not block

the super-spherical cavity 804.

Note: The above constitutes one embodiment of the first

version of the invention—one particular way to build it—but that particular

expression does not encompass all of the inventive concepts used in this

version. Many other ways of making and using this version using the same

concepts as used in this version will be obvious to one of average skill in the

art. The main concepts are as follows:

More on usable head rotation: For instance, the term

“horizontal” (usually used in context of a “horizontal swivel”) means

latitudinal enough for usable head rotation. For example, Osteoarthritis.com

gives the following values for normal hip rotation (minimal and maximal):

flexion (bending) 0-125; extension (straightening) 115-0; hyperextension

(straightening beyond normal range) 0-15; abduction (move away from central

axis of body) 0-45; adduction (move towards central axis of body) 45-0; lateral

rotation (rotation away from center of body) 0-45; medial rotation (rotation

towards center of body) 0-45. Ten to thirty degree flexion is necessary for

walking (Spina Bifida Association of America, sbaa.org), though lower degrees

of flexion still enable movement of the joint. For shoulder joint rotation,

Shoulder flexion 0-90; Shoulder extension 0-50; Shoulder abduction 0-90;

Shoulder adduction 90-0; Shoulder lateral rotation 0-90; Shoulder medial

rotation 0-90. Thus, any embodiment within the inventive concepts detailed

within this patent application that produces usable head rotation is therefore

usable. Note that for the cables version, rotation along the cup-cable and

independently along the head-cable is restricted to 180 degrees, unless the cup

is recessed (see below).

Note that “usable head rotation” means for repeated use

throughout the normal lifetime of an artificial hip joint, which is not

accomplished if for example the head-cable 202 slips out of

the groove 204 and doesn't allow for usable head rotation after

a week (for instance) of use.

A. The head to head-bone rod fastens at one end to “roughly

the south pole of the head” (or more exactly), and at the other end comprises a

rod to be inserted into the head-bone. (See for example FIG. 2). [“Roughly

the south pole of the head” means close enough to the south pole of the head to

allow for usable head rotation.] If the head-cable 202 passes through

“about the head's south pole”, [“about the head's south pole” means close

enough to the south pole to allow for usable head rotation] then the head to

head-bone rod 218 has a hole roughly at the south pole end to allow

the head-groove and head-cable to pass through about the south pole.

(See FIG. 9).

B. The head: The head 108 is “roughly a ball

shape” [meaning having spherical portions of the surface of the head 108 that

allow it to fit snugly within the spherical portions 506 of the

inner surface of the cup 802, even when the head 108 is

rotated along any axis allowed to any number of degrees allowed (in the context

of all of the parts put together), as well as having room for the

cup-cable 526 within the super-spherical cavity 804] that fits

inside the cup 106 and contacts the spherical

portions 506 of the inner surface of the cup 802 through

the cup-liner 531. “A head fitting inside the inner surface of the cup”

means the same thing as “roughly a ball shape”. The phrase “contacting the

spherical portion of the inner surface of the cup” contemplates direct contact

with the spherical portion of the inner surface of the cup and/or indirectly

through a cup-liner. Ideally, the head contacts all spherical portions of the

inner surface of the cup, but alternatively, the head contacts enough spherical

portions to allow for usable head rotation or more.

The head 108 has a “roughly longitudinal

groove” [meaning sufficiently longitudinal to allow for usable rotational

movement of the head 108 along the cup-cable 526 axis

in both directions and defined as a “head-groove” 204] looped around the

circumference of the head 108 running “roughly pole to pole”

[meaning both 1) going from the north pole of the head 1202 to

the south pole 1204 and back, and 2) changing direction in its

loop from northward to southward (and vice versa), closely enough to each pole

to allow for usable head 108 rotation, including but not limited

to rotational movement of the head 108 along the cup-cable 526 axis

in both directions]. Alternatively, the head-groove may be completely

longitudinal and run completely pole to pole, or anything in between this

exactitude and that allowing for usable head rotation. The phrase “fitting

inside the head-groove when the head-cable is between the head and the

spherical portion of the inner surface of the cup” means that those portions of

the head-cable that are currently between the spherical portion of the inner

surface of the cup and the head are inside the head-groove so as not to get

caught or pinched between the head's spherical surface and the spherical

portion of the inner surface of the cup. Alternatively, the head-cable can be

“looping around a portion of the head”, where the head cannot move

translationally away from the inner surface of the cup's north pole without the

head-cable tightening, or catching. This serves the same purpose of

constraining the head translationally as when the head-cable is “attaching to

the head” at at least two ends.

Note that while ball-bearings are included in the preferred

embodiment between the head 108 and the head-cable 202,

allowing the head 108 to rotate independently of the

head-cable 202, thus allowing the head-cable 202 to maintain its

shape when it loops around the cup-cable 526, thus obviating the need for

the head-cable 108 to be flexible 202, if the head-cable 108 is

flexible, then it can change its shape as the stretch of head-cable forming the

loop around the cup-cable 526 changes. (This change in shape can also

allow the head 108 to potentially rotate further than if the

head-cable was straight—see for example FIG. 11D showing the

head-cable line rotating further along the head 108 than in

the super-spherical cavity 804—see also FIG. 16D.) Additionally,

even if the head-cable 202 was not flexible, and the head 108 did

not rotate independently from the head-cable 202, there would still be

wiggle room before either an end of the loop of the head-cable 108 hit

the cup 106 or the head-cable 108 caught on the

cup-cable 526.

In another embodiment, a sheath 1304 encloses

the head-cable 202 for a portion (optionally and preferably the

complete length) of the head-cable 202 that does not need to come out

of the head-groove 204 to begin to loop around the cup-cable 526 during

usable head rotation (see FIG. 13A).

In yet another embodiment (see FIGS. 15A-15B), the

head-cable 1502 and/or head groove 1506 in

the head 1504 do not go around the south pole of

the head 1204, though the head-cable 1502 does make a

complete loop (no breaks in the head-cable 1502), obviating the need for

a hole 570 between the stem 110 and the south

pole of the head 1204, making the formerly pronged portion 564 into

a non-pronged portion 1306. Again, the geometry of the swerve around

the south pole of the head 1204 must 1) allow for usable head

rotation and 2) if no sheath (similar to the sheath 1304 in FIG.

13A) is used around the head-cable 1502, not allow for the

head-cable 1502 to slip out of the head-groove 1506 during

usable head rotation.

In yet another embodiment (see FIG. 13B), the

head-cable 202 and/or head-groove 204 do not go all the way

down to the south pole of the head 1204 and loop around it, but

attach 1302 to the head 1308 at certain latitudes

above the south pole of the head 1204 at each end. The latitudes

at each end where the head-cable 202 attaches 1302 to

the head 1308 must allow for usable head rotation, and the

formerly pronged portion becomes non-pronged 1306 because the

head-cable 202 no longer needs a hole 570 to go

through.

In another embodiment (see FIGS. 14A-14B), the

head-cable is forked 1406 (with accommodating forked head-groove 1404)

around the south pole 1204 of the accommodating head 1402,

again obviating the need for a hole 570 between

the stem 110 and the south pole of the head 1204,

making the pronged portion 564 into a non-pronged

portion 1306. Again, the geometry of the swerve around the south pole of

the head 1204 must 1) allow for usable head rotation and 2) if

no sheath (similar to the sheath 1304 in FIG. 13A) is used

around the head-cable 1502, not allow for the head-cable 1406 to

slip out of the head-groove 1404 during usable head rotation.

In yet another embodiment (see FIGS. 16A-16B), instead

of one head-cable 108, one head-cable 1604 in a

head-groove 1606 is used on one side of the south pole of

the head 1204, and another head-cable 1608 in a

head-groove 1610 in an accommodating head 1602 is used

on the other side of the south pole of the head 1204, again obviating

the need for a hole 570 between the stem 110 and

the south pole of the head 1204, making the pronged

portion 564 into a non-pronged portion 1306. Again, the

geometry of each head-cable 1608 around the south pole of

the head 1204 must 1) allow for usable head rotation and 2) if

no sheath (similar to the sheath 1304 in FIG. 13A) is used

around the head-cable 1502, not allow for the head-cable 1608 to

slip out of the head-groove 1610 during usable head rotation. Note

that any number of head-cables 1608 may be used, so long as they

allow for usable head rotation. It is best to have the head-cables 1608 parallel,

but they may be non-parallel if they still allow for usable head rotation.

In yet another embodiment (see FIG. 17), the above

embodiment (in the previous paragraph) with multiple head-cables is changed by

replacing the cup-cable 526 with two cup-cables 1702. Again, the

geometry must allow for usable head rotation. It is optionally useful to have

stretchable head-cables to obtain more degrees in the range of motion along

each axis.

In yet another embodiment (see FIG. 20), the

head-cable 2004 does not have any head-groove 204 but

attaches to the head 2002 at two points 2006 in

the northern hemisphere of the head 2002, again obviating the need

for a hole 570 between the stem 110 and the south

pole of the head 1204, making the pronged portion 564 into

a non-pronged portion 1306. Optimally, the head-cable 2004 attaches

at each end at 45 degrees from the north pole of the head 1202 on

opposite sides of the north pole, so as to allow the head 2002 to

rotate 45 degrees in each direction along the line of the head-cable 2004 before

either 1) the attachment point 2006 of the head-cable 2004 bangs

into the inner surface of the cup 802, or 2) the head-cable 2004 catches

on the cup-cable 526.

In yet another embodiment (see FIG. 2106), instead of

using a head-cable 202 and cup-cable 526, a head-cup-cable 2104 to

attach the inner surface of the cup 802 to

the accommodating head 2102 with attachment point 2106.

It is useful for the head-cup-cable 2104 to be stretchable and have

room to unfold itself and become longer (like a snake uncurling), so as to

increase the range of motion.

If it is not necessary for the head-cable to slide linearly

relative to a head-groove, then the head-cable must just fit these requirements:

1) it must be able to loop around the cup-cable during usable head rotation; 2)

it must not catch at the cup's equator between the head and the inner surface

of the cup (through the cup-liner).)

Though not optimal, it is not necessary for the head-cable

to be in the head-groove all of the way along the head, so long as usable head

rotation is obtained.

Though the cup 106 is shown in the figures

extending to the equator of the head and no further, the cup can extend down

beyond the equator of the head into the southern hemisphere, so long as usable

head rotation is obtained. This can be used as an additional safeguard to keep

the head from dislocating from the socket, but sacrifices range of motion to

the extent it encircles the head.

C. The cup: The cup is comprised of an inner

surface 802 and an outer surface 511, the outer

surface 511 fastened to the cup bone and the head fitting within the

cup's inner surface 802. (See for example FIG. 5 for

components mentioned in this paragraph).

The inner surface 802 is comprised of

a spherical portion 506 and a super-spherical (hollowed out

beyond spherical) portion 508.

Optionally and preferably the super-spherical

portion 508 of the inner surface of the cup 802 viewed

from the side is a portion of a circle with its center the same as

the spherical portion 506 but with a larger radius, also

optionally with sides that jut inward allowing the cup-cable 526 to

contact the inner surface of the cup 802 at a perpendicular

angle. However, so long as the cavity 804 allows room for the

head-cable 202 to loop around the cup-cable 526 and rotate

for usable rotation, there is enough concavity in the super-spherical

cavity 804.

Spherical Portion:

The spherical portion 506 of the inner

surface of the cup 802 “runs roughly all of the way around the

inner surface of the cup along latitude lines, is located roughly closer to the

cup's equator than the super-spherical portion, and extends approximately up

from the equator to a certain latitude on the inside surface of the cup”

[meaning also covering enough surface area along the head's equator 1206 to

accomplish the following: 1) once fitted into the spherical portion 506 of

the socket/cup 106, the head 108 cannot move

translationally further into the socket 106; and 2) the surface area

of the portion where the head 108 contacts the cup-liner 531 is

sufficient such that any debris buildup caused by rubbing of

the head 108 and the inner surface of the cup 802 against

the cup liner 531 does not unduly impair operation of the

apparatus nor the patient's health, rendering the hip implant unsafe to

implant]. Alternatively, the “inner surface wherein a portion of the inner

surface running from the cup's equator to a more northerly latitude” is defined

to runs all of the way around the inner surface of the cup along latitude

lines, extends upward from the cup's equator to a particular latitude (for

example, 5, 10, 20, 45 degrees upward from the cup's equator, these examples

not meant to be limiting).

Super-Spherical Portion:

The super-spherical portion 508 of the inner

surface of the cup 802 “runs roughly all of the way around the

cup along latitude lines, is located roughly closer to the cup's north pole,

and extends down approximately from the cup's north pole to said certain

latitude on the inner surface of the cup” [meaning also covering enough surface

area to allow usable rotational movement both along the line of the

cup-cable 526 and along the line of the head-cable 202].

Alternatively, there can be “a portion of the inner surface running from the

more northerly latitude to the north pole of the cup”, wherein the

super-spherical (same meaning as “hollowed out super-spherically”) portion runs

all of the way around the cup along latitude lines, and runs down latitudinally

from the north pole of the inner surface of the cup to the latitude at which

the spherical portion begins.

Connecting the Cup to the Cup-Bone:

The cup 106 is fastened to the cup-bone,

either directly or indirectly through a mounting plate (or other combination of

parts) (optionally and preferably with two screws into the cup-bone).

Divisions of Cup:

The cup 106 is comprised of an inner

surface 802 and an outer surface 511, the outer

surface 511 fastened to the cup bone (for example, hip

bone 102 or shoulder framework fitting around the cup 404) and

the head 108 fitting within the cup's inner surface 802.

The inner surface 802 is comprised of a spherical

portion 506 and a super-spherical 508 (hollowed out beyond

spherically) portion.

In yet another embodiment (See FIGS. 22A-C), the

portions of the cup along the cup's equator are recessed along the line of the

head-cable 202 (with one recess 2202 at one side, and

another recess 2204 on the opposite side), allowing

the stem 110 room to swing up beyond 180 degrees (see FIG.

22B) along the line of the head-cable. Note that the cup-liner 531 must

also similarly be recessed.

Optionally, the cup liner lines 531 at least

the spherical portions of the inner surface of the cup 802 and

contacts the inner surface of the cup 802 on one side and

the head 108 on the other side. (See for example FIGS.

3, 5).

Optionally, a locking ring for the cup liner 531 holds

the cup liner 531 in place, such as found in U.S. Pat. No.

7,766,971, hereby incorporated by reference.

The cup-cable 526 runs “roughly parallel to the

surface of the head above the north hemisphere and roughly perpendicular to the

head-groove” [meaning parallel enough to the surface of the head and

perpendicular enough relative to the head-groove to allow for usable head

rotation], attached at each end at a point on the super-spherical portion of

the inside surface of the cup (optionally with a lip that allows the cup-cable

to contact the inside surface of the cup at a perpendicular angle). (See for

example, FIGS. 13A-B). Alternatively, the cup-cable can run exactly

parallel to the surface of the head above the north hemisphere.

Cup-Cable/Head-Cable Interface:

In yet another embodiment (see FIGS. 18-19), the

head-cable 202 can slide linearly relative to an interface 1802,

while the cup-cable 526 can also slide linearly (though perpendicular

to the head-cable 202) relative to the interface 1802. This

allows the distance between the cup-cable 526 and the

head-cable 202 to remain fixed for easier motion.

The interface 1802 is composed of 1) a subunit 1804 with

a hole 1808 for the head-cable 202 housing a roller

bearing above the head-cable 1902 and a roller bearing below the

head-cable 1904; and 2) a subunit 1806 with

a hole 1810 for the cup-cable 526 housing a roller

bearing above the cup-cable 1906 and a roller bearing below the

cup-cable 1908. Note that any number of roller bearings (or other

bearings, such as ball-bearings, or multiple sets of bearings) may be used, so

long as the head-cable 202 and cup-cable 526 each can slide

independently. It is also possible to have only the cup-cable 526 able

to slide if ball-bearings 602 in the head groove 204 allow

the head 108 to rotate independently of the head-cable 202.

More on the Swivel:

The swivel allows the head-bone to rotate along the z-axis

(when you twist your leg (for the hip joint) or twist your shoulder (for the

shoulder joint) in the axis pointing from the inner surface of the cup's north

pole down to the head-bone, discussed earlier as “latitudinally”). Rotation

along this z-axis is called “horizontal”, resulting in the term “horizontal swivel.”

The swivel may be horizontal, or roughly horizontal enough to allow for usable

head rotation, or anything in between. The swivel may be at any workable point

between the head-bone and the cup-bone—thus, if it does not interfere with the

functioning of the other parts of the apparatus, such points which should be

obvious to one of ordinary skill in the art. The swivel also may be between the

inner surface of the cup 802 and the cup-bone (for example,

the hip bone 102 or the shoulder framework 404), or between

the inner surface of the cup 802 and the head 108, or

between the south 1204 pole of the head and the head-bone (for

example, the femur 112 or the humerus 402), or bisecting

the head 108 (so shoulder framework 404) remains “substantially

fixed” [meaning not susceptible to breakage or unusable bending that would

render the hip implant unsafe to be implanted] (aside from the horizontal

twisting afforded by the swivel) relative to the part adjacent to the swivel

further from the cup-bone (for example, the hip long as it doesn't interfere

with the head-cable 202 sliding in any head-grooves 204, and is

sufficiently strong so that the part adjacent to the swivel closer to the

cup-bone (for example, the hip bone 102 or the bone 102 or

the shoulder framework 404)). The swivel is optional, as

the head 108 may still rotate along either axis even if

horizontally the head-cable 202 is not strictly perpendicular to the

cup-cable 526.

It should be obvious to one of ordinary skill in the art,

using the main concepts and the first version to work off of, to make and use

different versions using a) various means of connection (instead of screws,

substituting other ways of connecting the parts); b) splitting a given part

into multiple parts (for instance, to allow for assembly of most parts outside

of the body, and to allow parts to be more easily replaced (for instance, so

the bone doesn't have to be drilled into)), and/or combining parts; c) varying

numbers along ranges (for instance, the size of the head, exact shape of

super-spherical cavity so long as it performs its function, exact latitude at

which the inner surface of the cup shifts from super-spherical to spherical,

exact placement and design of the horizontal swivel, among others); and/or d)

omitting features so long as the function of usable head rotation is still

served. While different type heads (or other parts) are referred to throughout,

the usage of a specific reference numeral (such as 108) is not meant to

constrain the meaning if other geometries (including but not limited to parts

from other embodiments and/or other versions) are workable within the general

inventive concept, but just to be an example.

It should be obvious to a person of ordinary skill in the

art how to assemble any of the previously mentioned versions, with the