Invention (Patent Application Publication): Howald R,

Heuberger P, Trommsdorff U. Implant, WO2007090790A2 (2007).

WO2007090790A2 Switzerland

Inventors: Ralph Howald, Peter Heuberger, Ulrike Trommsdorff

Worldwide applications 2007 WO EP US

Application PCT/EP2007/051008 events:

2007-02-02 Application filed by Zimmer Gmbh

2007-02-02 Priority to US12/278,835

2007-02-02 Priority to EP07726285A

2007-08-16 Publication of WO2007090790A2

2007-12-06 Publication of WO2007090790A3

Implant

Ralph

Howald, Peter Heuberger, Ulrike Trommsdorff

Abstract

The invention relates to an implant for the relief of

damaged regions of the joint surfaces of hip or shoulder joints which may be

introduced into the gap between the joint surfaces of the joint head (11) and

the joint socket (13) in the natural joint, the implant being embodied as a

shell or cap which is laid in the implanted state with a convex outer surface

(29) in the joint socket (13) and a convex inner surface (31) sitting on the

joint head (11). The implant has a body section (15, 17) forming the shell or

cap with an opening (27) and a boundary section (19) defining the opening (27)

and the implant is made from a flexible material which may be deformed for

introduction of the implant into the gap between the joint surfaces.

Description

The invention relates to an implant for the relief of

damaged areas of the articular surfaces of hip or shoulder joints.

In known joint

prostheses usually both articular surfaces are replaced by coordinated

artificial joint parts. As is known, this takes place within the scope of

surgery, in which a more or less large part of the healthy bone is removed,

depending on the prosthesis used in each case. In hip surgery, for example, the

femoral head is partially or completely removed to make room for a condyle that

is usually anchored in the femur via a shaft. Accordingly, at the acetabulum

(acetabulum) of the hip bone by appropriate processing during surgery bone

material removed to attach an artificial socket or joint cup can, which serves

to accommodate the artificial condyle.

Such operations are

associated with considerable burdens and risks for the patient. A problem

particularly in relatively young patients is that proper function of an

artificial joint can not be guaranteed for any length of time. In many cases,

follow-up surgery is required. However, such revisions are often difficult to

carry out, since even the first operation has cost the patient a not

inconsiderable part of the healthy bone material.

The first surgery

that results in relevant loss of bone material may be delayed by so-called

resurfacing techniques become. Here, only the surfaces of the affected joints

are replaced by comparatively thin, cap or cup-shaped implants. However, these

known techniques require stressful operations, which are also not minimally invasive

possible. Furthermore, resurfacing also requires the removal of healthy bone

material in the area of the involved articular surfaces, albeit to a lesser

extent than in the aforementioned operations.

These considerations

are especially important when the articular surfaces are affected by arthrosis

and the involved bones themselves are intact, i. E. no fractures need to be

treated. Such joint damage also occurs in relatively young patients, which is

why there is a need for techniques for the treatment of damaged joint surfaces,

in which the healthy bone material should remain as possible. To minimize the

burden on the patient, such techniques should be minimally invasive.

It is the object of

the invention to provide an implant which meets these requirements.

The invention

provides an implant for relief of damaged areas of the articular surfaces,

which can be introduced into the gap between the interacting in the natural

joint articular surfaces of the condyle and the acetabulum, wherein the implant

is designed as a shell or cap in the implanted state with a convex Outer side

is located in the socket and sits with a concave inner side on the condyle,

wherein the implant comprises a shell or cap forming body portion having an

opening, and an edge portion which defines the opening, and wherein the Implant

is made of a flexible material which is deformable for introducing the implant

in the existing between the joint surfaces gap.

The implant can

significantly reduce pressure and / or shear loads on arthrosis affected areas

of the articular surfaces. As a result, the implant is not exclusively

suitable, but especially well for joints affected by osteoarthritis in the

early stages.

The time at which a

first operation of the type described above becomes inevitable, can be pushed

out through the implant. Therefore, the implant is not exclusive, but

especially interesting for relatively young patients.

The advantage is

that the implant can be used as part of a minimally invasive procedure. There

is no processing of the bone required. The implant can be designed so that it

aligns itself in the joint space. Alternatively, the implant can be fixed to

the natural bone or tissue structures.

Furthermore, it is

advantageous that the insertion of the implant does not require subluxation of

the condyle.

It has been found

that by a suitable material and / or by a suitable material coating for the

implant, the natural joint function can be maintained upright.

The implant can be

made of one or more different metallic or non-metallic materials. In question

is, for example, a hydrogel, polyurethane or polyethylene. The implant may

contain a textile material or consist of a textile material, wherein the

textile material comprises a textile substrate, and wherein at least on a part of

the surface of the textile substrate, a coating is provided which is one of the

hydrogels, polyurethanes, polyvinyl chloride, Polytetrafluoroethylene and any

combination of two or more of the aforementioned compounds selected compound.

The textile substrate

may be made of fibers, at least a portion of the fibers being provided with a

coating containing a compound selected from the group consisting of hydrogels,

polyurethanes, polyvinylchloride, polytetrafluoroethylene and any combination

of two or more of the aforementioned compounds.

This makes it

possible to realize gliding properties that at least largely correspond to the

natural conditions in the joint.

Furthermore, the

implant may have a sandwich construction of a plurality of individual layers.

At least two layers may differ from one another in terms of their construction

and / or their material.

The implant or at

least one layer of a sandwich construction of the implant comprising a

plurality of individual layers may be provided with a textile, fibrous, braid,

knit or fabric reinforcement.

Two adjacent layers,

which have the same material but a different structure, can be chemically mixed

with one another be, wherein the crosslinking was generated for example by

irradiation.

The material of the

implant may be bioresorbable.

Furthermore, it can

be provided that the implant comprises a plurality of respectively a partial

area of the outside and / or the inside forming relief elements. The relief

elements can be designed as upholstery, cushions or bales. The relief elements

can be connected to each other by a flat support structure. The support

structure may comprise a textile, fiber, braid, knit or fabric material.

The edge portion may

be provided with a reinforcement. In the edge section separate strength carrier

can be integrated. A reinforcement of the edge portion can be made by a fiber

or cord structure.

It is also possible

that the edge portion is hollow and provided with a filling. The filling may be

a gas, for example air, or a liquid. It may be provided a filler whose state

changes with time. While the filler material is liquid or pasty upon insertion

of the implant to facilitate insertion, over time, the filler material

transitions to a solid state such that the rim portion imparts high dimensional

stability to the implant and / or for stable positioning of the implant between

the two articular surfaces.

The body portion of

the implant may comprise a ball portion and a cylinder portion, the cylinder

portion being attached to the ball portion. cut connects. The ball portion may

have the shape of a hemisphere.

The edge portion may

be thickened relative to the wall thickness of the body portion. It can be

provided that the edge portion is formed bead-shaped.

Depending on the

respective joint, the implant can be dimensioned such that in the implanted

state the edge section is located outside the gap existing between the joint

surfaces.

In order to

facilitate deformation of the implant during insertion and / or to take into

account the anatomy of the relevant joint, the body portion of the implant may

have at least one recess. When used on the hip, this recess can serve to

preserve the so-called Hüftkopfband (ligamentum capitis femoris).

The recess may

extend into the edge portion, wherein the edge portion may have an interruption

formed by the recess. A separate fitting may be provided which, after inserting

the implant into the gap between the articular surfaces, may be inserted into

the interruption of the rim portion to close the rim portion. The fitting can

thus give the implant in the inserted state dimensional stability again.

It is possible, but

not mandatory, for the implant to have a constant wall thickness. If a recess

of the type described above is provided, then the wall thickness of the body

portion of the vary in that the wall thickness near the recess is greater than

in the region further away from the recess.

In one possible

embodiment, a wall thickness distribution results in that, starting from a

symmetrical state in which the body portion has a constant wall thickness

between the inside and the outside, the inside and the outside are shifted from

one another. This offset may be in a direction parallel to an equatorial plane

of a sphere portion of the body portion.

If a recess of the

type described above is provided, then the offset of the inside relative to the

outside in a direction away from the recess. This results in a distribution of

the type already mentioned above, according to which the wall thickness in the

area of the recess is greater than in areas removed from the recess.

Other possible

embodiments will be apparent from the dependent claims, the description and the

drawings.

The invention will

now be described by way of example with reference to the drawings. Show it:

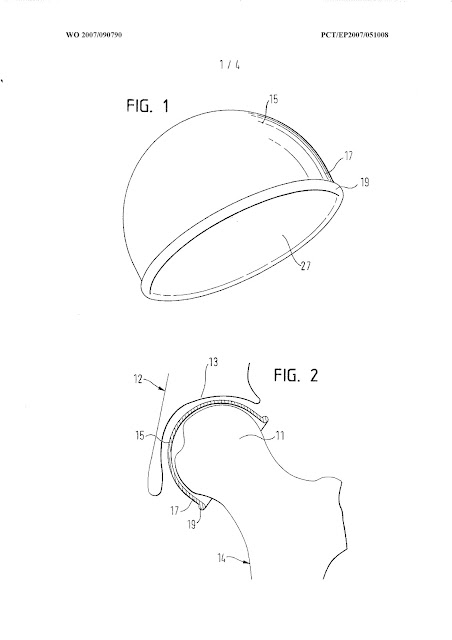

Fig. 1-3 an embodiment of an implant according to the invention,

and

Fig. 4-7, another

embodiment of an implant according to the invention. The implant can be used

for both hip joints and shoulder joints. Two embodiments will be explained

below, for example only in connection with the hip joint.

The implant

according to FIGS. 1 to 3 is designed as a cap, which comprises a sphere

section 15 in the form of a hemisphere. At the ball portion 15, a cylindrical

portion 17 connects.

The cap is open at

the bottom. The opening 27 is delimited by an edge section 19. The edge portion

19 comprises a bead-shaped thickening such that the edge portion 19 projects

radially outward relative to the cylinder portion 17.

The insertion of the implant can take place within the

framework of an arthroscopic procedure. The joint Surfaces can be separated,

for example, e.g. by use of an extraction table, and indeed without subluxation

of the femoral head 11. The insertion of the implant can also take place by

other minimally invasive procedures.

The implant consists of a flexible material. In this way, the implant can be deformed

during insertion and adapt to the shape of the joint gap between the femoral

head 11 and the socket 13. With regard to the possible materials or the

possible structure of the implant, reference is also made to the introductory

part.

The material may be

metallic or non-metallic. In question is, for example, a hydrogel, polyurethane

or polyethylene. The material can be reinforced by fiber or canvas structures.

Furthermore, the material can consist of several layers or layers, which are

either made of different materials or of the same material with the same

material. Different structures are made. The implant material may comprise a

substrate and a substrate coating. The substrate may be a textile material.

For example,

referring to FIG. 3, the inner radius A of the ball portion and the cylinder

portion may be in the range of 38-60 mm. The length D of the cylinder portion

17 is, for example, half of the inner radius A or less. The cylinder portion 17

may be arbitrarily short, with a cylinder portion 17 can be completely

dispensed with.

The wall thickness C

of the implant is constant and is for example 0.5 to 3 mm.

The bead-shaped edge

portion 19 is at least approximately circular in cross section. The radius E of

the bead is, for example, in the range of 0.5 to 4.0 times the wall thickness

C.

The bead-shaped edge

portion 19 may be solid and made entirely of the same material as the body

portion formed by the ball portion 15 and the cylinder portion 17.

Alternatively, the edge portion 19 may be reinforced by a cord structure, for

example. It is also possible to make the edge section 19 hollow and to be

filled with a gas, a liquid or a material which over the course of time changes

from a liquid or pasty initial state to a solid final state, as explained in

the introductory part.

With a corresponding

configuration, the bead-shaped edge portion 19 can ensure that the implant aligns

itself in the inserted state. In order to prevent relative movements between

the implant and the socket pan 13 or to reduce the extent of these movements

when moving the joint, the implant can be fastened to the edge area of the

acetabulum, namely on the bone or on the fibrocartilaginous material of the

labrum acetabuli.

It is also possible

to fasten the edge section 19 of the implant to the femoral neck, wherein a

possibly provided cord reinforcement of the edge section 19 can be used. As a

result, femoral articulation of the implant can be prevented or reduced in its

extent.

The embodiment

according to FIGS. 4 to 7 differs from the exemplary embodiment according to

FIGS. 1 to 3 by a recess 21 provided in the body section 15, 17 and by a

non-constant wall thickness.

The recess 21 extends from the ball section 15 via the

cylinder section 17 into the edge section 19. The edge section 19 is interrupted due to the recess 21. In order to

close the interruption again after insertion of the implant and to restore the

dimensional stability of the implant, a separate fitting piece 23 is provided.

When inserting the

implant, the fitting piece 23 is removed. The implant is pushed from the

cranial edge of the acetabulum 13 between the articular surfaces of the femoral

head 1 1 and the hip bone 12. Here, the flexible implant adapts itself to the

shape of the joint surfaces. As already mentioned, due to the recess 21 the

ligamentum capitis femoris 33, which is located in the implanted state in the

region of the recess 21 (FIG. 5).

The edge portion 19

can then be closed by the fitting piece 23. As a result, the implant again

acquires a dimensional stability in accordance with the exemplary embodiment

without a recess according to FIGS. 1 to 3.

A slight asymmetry

in wall thickness distribution, as described below, provides the implant with

rotational stability. Stability to rotation can also be achieved by fixing the

edge section 19 of the implant at the edge region of the acetabulum 13.

With regard to the

material and the structure of the implant, reference is made to the

explanations of the embodiment of FIG. 1 to 3.

The non-uniform wall

thickness distribution of the implant arises as a result (FIG. 6) that the

outer side 29 and the inner side 31 are displaced from one another with a

constant wall thickness starting from a symmetrical state along a line k, which

runs parallel to an equatorial plane Q. In other words, the outer side 29 and

the inner side 31 form two eccentrically adjacent spherical partial surfaces.

The direction of the displacement is chosen such that the inner side 31 is

displaced away from the recess 21. The center Ma of the inner side 31 thus lies

on the side of the center Mb of the outer side 29 facing away from the recess

21.

In this case, these center points Ma, Mb and the

center O of a circular region of a projection of the recess 21 lie on the

equatorial plane Q on a line k (FIG. 7). The circular area with Telpunkt O has a diameter G, which is basically

arbitrary, as long as the recess 21 does not reach to the pole of the implant

(Fig. 6). It is therefore possible to define two half-spaces which are

separated from each other by a plane T in which the center Mb of the outer side

29 lies, through which the center axis Zb of the corresponding outer surface of

the cylinder section 17 extends. In the one half space is the recess 21, while

in the other half space of the center Ma of the inner side 31 and the central

axis Za of the corresponding inner surface of the cylinder portion 17 are.

The size of the inner

radius A and the length D of the cylinder portion 17 may be sized according to

the embodiment of FIG. 1 to 3. The difference between outer radius B and inner

radius A is, for example, in the range of 0.5 to 3 mm. The radius E of the

bead-shaped edge portion 19 is, for example, in the range of 0.5 to 3.0 times

the aforementioned difference between outer radius B and inner radius A.

The offset F between

the two centers Ma and Mb and thus the central axes Za, Zb can be up to 2.5 mm.

The above-explained

direction of the offset F along the line k results in the greater wall

thickness in the region of the recess 21 and thus in the caudal region of the

acetabulum.

As an alternative to

the materials and the structure of the implant, as explained above and in connection

with the exemplary embodiment according to FIGS. 1 to 3, the implant can

consist of a plurality of soft individual elements which are formed in a

cushion, pillow or bale shape and serve as relief elements. The relief Elements

define the contact surfaces of the implant to the articular surfaces of the

femoral head 1 1 and the acetabulum 13 and thus serve to relieve already

damaged areas of the articular surfaces. The relief elements are interconnected

by a flat support structure, which may consist of a metallic or non-metallic

material. The support structure may comprise a textile, fiber, braid, knit or

fabric material.

In each of the

described embodiments, the invention provides an implant, by means of which the

damaged areas of the joint surfaces can be relieved. This relief can cause the

damaged areas to recover. Patient-burdening operations that result in the loss

of healthy bone can be delayed in this way. As already explained, this is of

great advantage, above all for relatively young patients.

LIST OF REFERENCES

11 condyle

12 hip bones

13 socket

14 femur

15 ball section 17

cylinder section

19 edge section

21 recess 23 fitting

piece

27 opening

29 outside

31 inside

33 Ligament of

capitis femoris

A inner radius

B outer radius

C Wall thickness of

the body section

D length of the

cylinder section

E radius of the

bead-shaped edge section

F offset

G diameter of the

circular area of the recess

O center of the

circular area of the recess

Q equatorial plane

T level

Ma center of the inside

Mb center of the

outside

Za central axis of

the inner surface of the cylinder portion

For example, center

axis of the outer surface of the cylinder portion k connecting line between Ma

and Mb

Claims:

1. An

implant for relieving damaged areas of the articular surfaces of hip or

shoulder joints, which can be introduced into the gap between the articular

joint surfaces of the joint head (11) and the joint socket (13), wherein the

implant is designed as a shell or cap, which is located in the implanted state

with a convex outer side (29) in the socket (13) and with a concave inner side

(31) on the condyle (11) sits, said implant forming a shell or cap body portion

(15, 17) and having an edge portion (19) defining the opening (27), and wherein

the implant is made of a flexible material that is deformable for insertion of

the implant into the gap present between the articular surfaces ,

2. Implant according to claim 1, characterized in that the

implant is made of one or more different non-metallic materials, for example of

a hydrogel, polyurethane or polyethylene.

3. Implant according to claim 1 or 2, characterized in that

the implant contains a textile material or consists of a textile material,

wherein the textile material comprises a textile substrate, and wherein at

least on a part of the surface of the textile substrate a coating is provided

which is one of hydrogels, polyurethanes, polyvinyl chloride,

polytetrafluoroethylene and any combination of two or more of the

aforementioned compounds.

4. Implant according to one of the preceding claims,

characterized in that the implant contains a textile material or consists of a

textile material, wherein the textile material comprises a textile substrate,

and wherein the textile substrate consists of fibers and at least a part of the

Fibers are provided with a coating which contains a compound selected from the

group consisting of hydrogels, polyurethane, polyvinyl chloride,

polytetrafluoroethylene and any combination of two or more of the

aforementioned compounds.

5. Implant according to one of the preceding claims,

characterized in that the implant is made of a bioresorbable material.

6. Implant according to one of the preceding claims,

characterized in that the implant has a sandwich construction of a plurality of

individual layers.

7. Implant according to claim 6, characterized in that at

least two layers differ from each other in terms of their structure and / or

their material.

8. Implant according to one of the preceding claims,

characterized in that the implant or at least one layer of a sandwich

construction of the implant, which has a plurality of individual layers, with a

textile, fiber, braid, knitted or Gewebever strengthening is provided.

9. Implant according to one of claims 6 to 8, characterized

in that two adjacent layers, which have the same material, but a different

structure, are chemically crosslinked with each other, wherein the crosslinking

was generated for example by irradiation.

10. Implant

according to one of the preceding claims, characterized in that the implant

comprises a plurality of each a portion of the outer side (29) and / or the

inner side (31) forming relief elements, which are each formed as a cushion,

cushion or bale, wherein the relief elements are interconnected by a flat

support structure.

1 1. Implant

according to claim 10, characterized in that the support structure is a

textile, fiber, mesh, or Gewirk Includes fabric material.

12. Implant according to one of the preceding claims,

characterized in that the edge portion (19) is provided with a reinforcement.

13. Implant according to one of the preceding claims,

characterized in that in the edge portion (19) separate strength members are

integrated.

14. Implant according to one of the preceding claims,

characterized in that the edge portion (19) is reinforced by a fiber or cord

structure.

15. Implant according to one of the preceding claims,

characterized in that the edge portion (19) is hollow and provided with a

filling.

16. Implant according to one of the preceding claims,

characterized in that the body portion comprises a ball portion (15) and a

cylinder derabschnitt (17), which adjoins the ball portion (15).

17. Implant according to claim 16, characterized in that the

ball portion (15) is a hemisphere.

18. Implant according to one of the preceding claims,

characterized in that the edge portion (19) is formed so that it gives the body

portion (15, 17) in the implanted state dimensional stability.

19. Implant

according to one of the preceding claims, characterized in that the implant is

dimensioned such that in the implanted state, the edge portion (19) is located

outside of the existing gap between the Gelenkflä-gap.

20. Implant according to one of the preceding claims,

characterized in that the edge portion (19) opposite the wall thickness C of

the body portion (15, 17) is thickened.

21. Implant according to one of the preceding claims,

characterized in that the edge portion (19) is formed bead-shaped.

22. Implant according to one of the preceding claims,

characterized in that the body portion (15, 17) has a recess (21).

23. Implant according to claim 22, characterized in that the

recess (21) extends into the edge portion (19) and the edge portion (19) has an

opening formed by the recess (21).

24. An implant according to claim 23, characterized in that

a separate fitting piece (23) is provided, which after the introduction of the

implant into the gap between the joint surfaces in the interruption of the edge

portion (19) is insertable to close the edge portion (19).

25. Implant according to one of claims 22 to 24,

characterized in that the wall thickness of the body portion (15, 17) near the

recess (21) is greater than in the recess (21) further away regions.

26. Implant according to one of the preceding claims,

characterized in that, starting from a symmetrical state in which the body

portion (15, 17) has a constant wall thickness between the inside (31) and the

outside (29), the inside (31) and the outer side (29) are shifted from each

other.

27. Implant according to claim 26, characterized in that the implant has a recess (21) and the inner side (31) is displaced in a direction away from the recess (21).

External links

Howald R, Heuberger P, Trommsdorff U. Implant. WO2007090790A2 February 2, 2006. 2007. patents.google [Deu]

Howald R, Heuberger P, Trommsdorff U. Implant and a method for partial replacement of joint surfaces. US20090048679A1 February 2, 2006. 2009. patents.google [Eng]

Publications

of invention

EP1965736 (A2)

US2009048679 (A1)

WO2007090790 (A2)

WO2007090790 (A3)

2007HowaldR_TrommsdorffU

Authors & Affiliations

Ralph Howald,

Gossau (CH)

Peter Heuberger,

Raterschen (CH)

Ulrike

Trommsdorff, Zurich (CH)

Keywords

ligamentum capitis femoris, ligamentum teres, ligament

of head of femur, endoprosthesis, prosthesis,

invention, unipolar, subtotal

NB! Fair practice / use: copied for the purposes of criticism, review, comment, research and private study in accordance with Copyright Laws of the US: 17 U.S.C. §107; Copyright Law of the EU: Dir. 2001/29/EC, art.5/3a,d; Copyright Law of the RU: ГК РФ ст.1274/1.1-2,7

Comments

Post a Comment